Managing Supply Chain Disruptions with DDAE in 2023

December 23, 2022

DDMRP Formation Online and Demand Driven Leader (DDL) Courses from Patrick Rigoni

January 13, 2023Supply chain management (SCM) is a vital component of modern businesses and plays a key role in determining their success or failure. In the forthcoming years, we expect to see several significant trends in SCM that will shape how businesses operate and compete.

In this article, we’ll look at the top trends in SCM that are likely to dominate the landscape in 2023 and how the demand-driven adaptive enterprise (DDAE) model is stepping up to meet future challenges.

Here are the top 10 future trends in supply chain management in 2023:

-

Supply chains are going green

Climate change advocacy organizations and consumers’ increased attempts to be more ecologically responsible encourage the supply chain to become less environmentally destructive. Because electricity and transportation contribute significantly to greenhouse gas emissions in the United States, green logistics are swiftly gaining support among many businesses today.

Green logistics is just one of several supply chain developments influencing warehousing. Eco-friendly warehouses, for example, have comprehensive energy management systems that utilize timers and gauges to monitor the facility’s electricity, heat, water, and gas usage—these systems aid in reducing resource waste. Electric and solar-powered vehicles are also becoming more popular in supply networks; these vehicles help to minimize supply chains’ overall carbon impact.

Likewise, climate-smart supply chain planning is projected to play a more important role in SCM in the coming year and beyond. Changes in the environment driven by climate change affect the availability of goods and resources, potentially disrupting supply chains. Companies must evaluate these factors and, if necessary, seek additional help.

With the rise of green consumption, more businesses are projected to integrate eco-friendly supply chain operations. Aside from contributing to environmental preservation, firms that make sustainable efforts stand to gain more profit and consumer loyalty. After all, more than 60% of buyers are ready to pay a premium for environmentally friendly products.

-

Increased use of automation and AI

In several industries, the usage of artificial intelligence (AI) and automation is increasing. Automation, which has existed for decades, uses technology to reduce human inputs and is a machine completing a series of tasks. Automation could be more intelligent, implying that the technology only accomplishes activities explicitly designed for it.

On the other hand, AI aims to replicate characteristics of human intellect and may “learn” on its own to assist with more complicated, difficult jobs. AI still requires some human input, but it also uses machine learning to select the following steps without explicit human guidance.

AI and automation are valuable tools that help speed up your supply chain and keep you competitive in your niche in a world where speed and precision are critical for success. If you don’t use them, your competitors will, and you’ll fall behind as they achieve more success. Whether you employ AI or not, you should simplify your supply chain for the sake of the business.

According to Deloitte: “79% of organizations with high-performing supply chains have revenue growth that exceeds the industry average, while enterprises with optimized supply chains have 15% lower supply chain expenses, less than 50% inventory holdings, and 3X faster cash-to-cash cycles.”

-

Supply chains will use more integrations

As firms seek to form alliances and establish integrations with other parties, more components will be added to the supply chain in the coming years. Collaboration with third-party services can help businesses cut expenses while increasing customer service.

Integrations are especially advantageous for shippers who frequently convey their products by sea and land. Integrated services reduce delivery times and improve customer service.

The Amazon Effect also encourages businesses to optimize their supply networks to the greatest extent possible. As an outcome, more supply chain managers will collaborate with third-party logistics providers (3PLs) and technologies based on 3PLs. Companies can use 3PL providers to organize their supply chains because they offer inbound and outbound freight management and order fulfillment on any channel.

Similarly, 3PL-based solutions enable supply chain managers to integrate and connect numerous management systems to the cloud via API. Supply chain managers will be able to overcome the limits of in-house technology solutions thanks to these integrations.

Companies will also explore collaborations with other businesses that use digital technologies to provide more precise delivery ETA predictions and reduce administrative effort.

-

Strengthened relationships and human interactions

Technology is a powerful force in supply chain management, but so are the people who use it. Maintaining positive human interactions should be a top priority for every organization if not the top priority. It’s always a good idea to prioritize strengthening your connections with team members, vendors, and suppliers to promote collaboration and cooperation at every stage of the supply chain.

Your priority should be thorough, accurate, and timely communication. Good communication is not only the first step in developing any connection; it can also give you vital operational data and insight. This additional information can be used to improve your external and internal processes, making them more streamlined and efficient.

-

Use of blockchain

Most companies’ top worry today is supply chain visibility, so it’s not surprising that more organizations will try integrating blockchain technology into their supply networks. Blockchain technology has the potential to make the entire supply chain more transparent, reducing disruptions and improving customer experience. All supply chain components can be connected to a single platform using blockchain.

Shipping lines, carriers, forwarders, and logistics providers can all utilize the same platform to keep firms and customers up to speed on the status of their products. Payments and invoicing can both be made using the same system. This integration facilitates the entire supply chain and assists supply chain managers in detecting problems before they occur.

Blockchain also delivers unrivaled information security because the technology’s decentralized mechanism prevents data from being changed. Before any changes to the data are applied, all users must agree to them.

-

Rise of customized products

Expect an increase in customization in many portions of the supply chain, which may necessitate segmenting your supply chain and developing a customized strategy and approach for each segment.

Customers, in particular, will continue to expect a tailored experience from your company. Keeping up with significant customization needs might take time, and you’ll need to consider several options. One solution is customizing your manufacturing services, such as CNC machining and injection molding, as you work to produce prototypes and accelerate production without losing quality or precision.

Increasing personalization becomes more feasible as you focus on enhancing other areas of your supply chain. For example, you automate your order processing system by placing regular orders in one area and customized orders in another. In that case, you may find it easier to manage unique customer requests. By looking for ways to simplify other aspects of your organization, you will be able to dedicate more time and attention to product customization.

-

Internet of Things

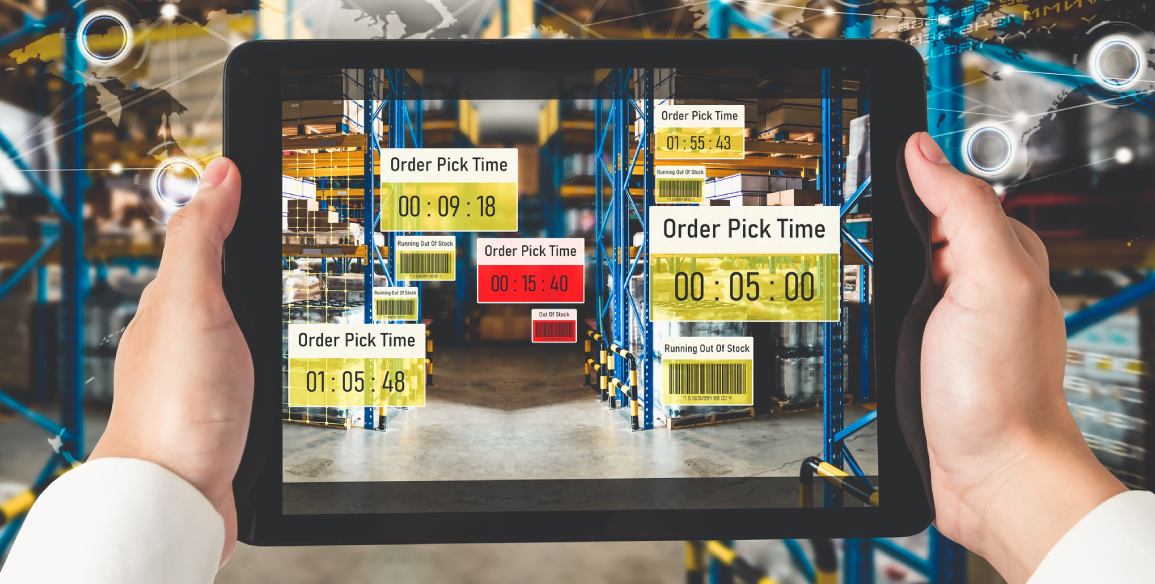

Aside from blockchain, many businesses are integrating IoT devices to improve supply chain visibility. For example, airplanes, trucks, and other transportation forms can be outfitted with sensors that provide real-time tracking updates on freight and delivery. In warehouses and retail outlets, IoT technology can also enhance transparency in production, inventory management, and predictive maintenance.

Companies can use this real-time data to anticipate customer needs, reduce downtime, and improve overall supply chain efficiency. IoT devices can also help firms maximize their assets and ROI by increasing visibility across supply chain components. Developing a digital supply network that is consistent with one’s company strategy and includes risk management procedures can assist organizations in building resilience to offset the impact of disruptive events such as the COVID-19 pandemic.

Many firms will also harness the power of IoT by connecting it with fundamental business tools like business intelligence software. These interfaces will enable analytics for IoT device data, allowing businesses to make data-driven decisions on supply chain strategy.

-

Resilience and risk management

The supply chain is continually in danger of interruption in an increasingly dynamic and uncertain environment. You can’t control the weather, forecast political events, or predict the consequences of a pandemic, but you can influence how your supply chain prepares for and responds to these dangers.

-

Elastic logistics

More is needed for supply chains to have lean operations; they must also be adaptable and sensitive to market swings. As a result, more companies are taking a more flexible approach to logistics.

Elastic logistics enable the supply chain to grow or contract in response to market needs rapidly. Artificial intelligence, for example, enables supply chains to alter as required with minimal disturbance.

-

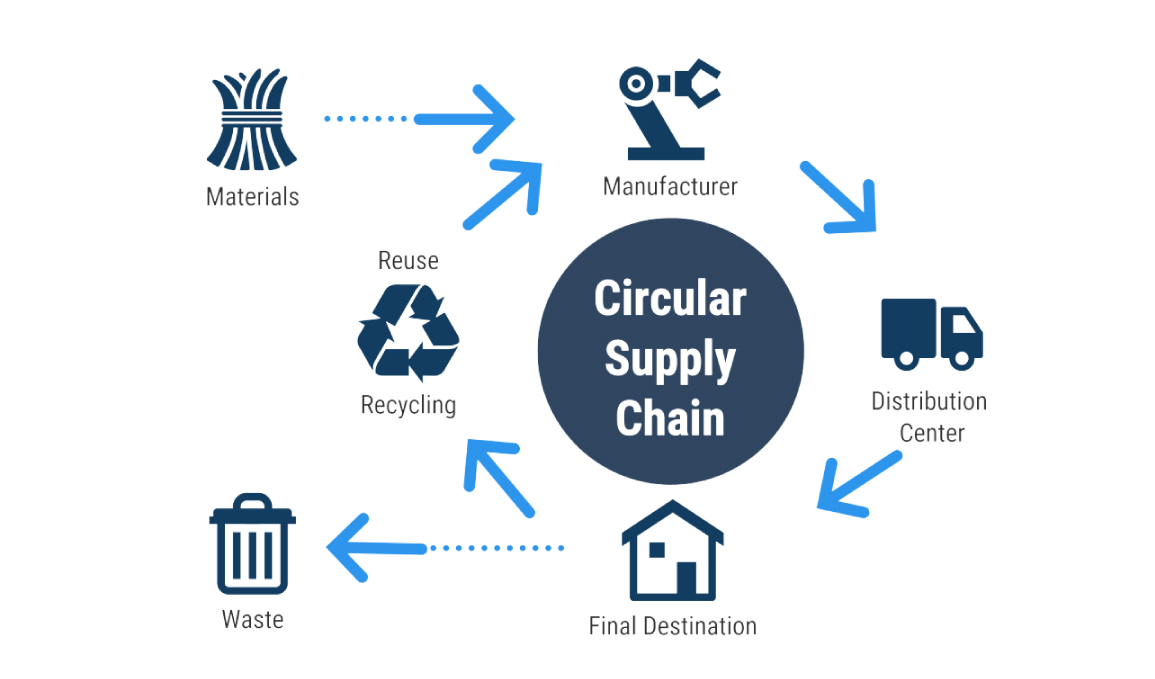

Circular supply chain

Circular supply chains, in which manufacturers rehabilitate abandoned products for resale, may soon replace linear supply chains. To deal with escalating raw material costs and fluctuating availability, many businesses break down their products and return them to their raw material form.

Looping the supply chain can help reduce expenses beyond the initial costs of implementing new processes. Companies that use a circular supply chain can spend less on raw materials, reducing price volatility risk. Furthermore, a circular supply chain generates less waste, allowing businesses to lower their overall environmental effect.

DDAE model and supply chain

The demand-driven adaptive enterprise (DDAE) model is an emerging approach to SCM that is well-suited to meet future challenges. The DDAE model is focused on adapting to changing customer and market demands and is characterized by high flexibility and agility.

DDAE is based on the idea that businesses should be able to quickly and easily adapt to changes in the market and customer demands. To do this, the DDAE model relies on real-time data and analytics to make informed decisions and respond to changes in demand. This approach requires a high degree of collaboration and communication within the organization and with external partners, as well as advanced technologies such as AI and the IoT.

One key advantage of the DDAE model is its ability to create a more efficient and agile supply chain. Businesses can reduce waste and optimize their operations by continuously monitoring and adapting to changing demands. This can lead to expense savings and improved customer satisfaction.

Conclusion

Many significant trends, including automation, AI, and the increasing importance of blockchain, will likely characterize the future of SCM. The DDAE model is well-suited to meeting these challenges and will likely become an increasingly important approach to SCM in the coming years.

Interested in knowing how Patrick Rigoni can step up the game of your supply chain? Contact us today and get a free consultation.

Patrick Rigoni also offers in-depth DDMRP courses; if you are interested to know more about DDMRP for the supply chain for your company, here is the link to the NEW DDMRP Page.