The Role of Digital Twins in Simulating and Optimising DDMRP Processes

July 24, 2024

Leveraging AI and Machine Learning in Inventory Management

August 9, 2024The supply chain landscape has seen significant transformations over the years, driven by advancements in technology and evolving market demands. One of the most notable shifts has been the adoption of Demand Driven Material Requirements Planning (DDMRP) and the integration of cloud-based solutions. This article examines the transformative impact of cloud technologies on DDMRP implementations, exploring how cloud computing enhances scalability, flexibility, and accessibility of data. These enhancements enable real-time decision-making and improved supply chain visibility, contributing to operational resilience and competitive advantage in the digital age.

Understanding DDMRP

The Evolution of Supply Chain Planning

Traditional supply chain planning methodologies, such as Material Requirements Planning (MRP) and Enterprise Resource Planning (ERP), have long been used to manage inventory and production processes. However, these systems often fall short in dynamic and unpredictable market environments. Enter DDMRP, a methodology that combines the best aspects of MRP, ERP, and Lean principles to create a more responsive and demand-driven supply chain.

Key Components of DDMRP

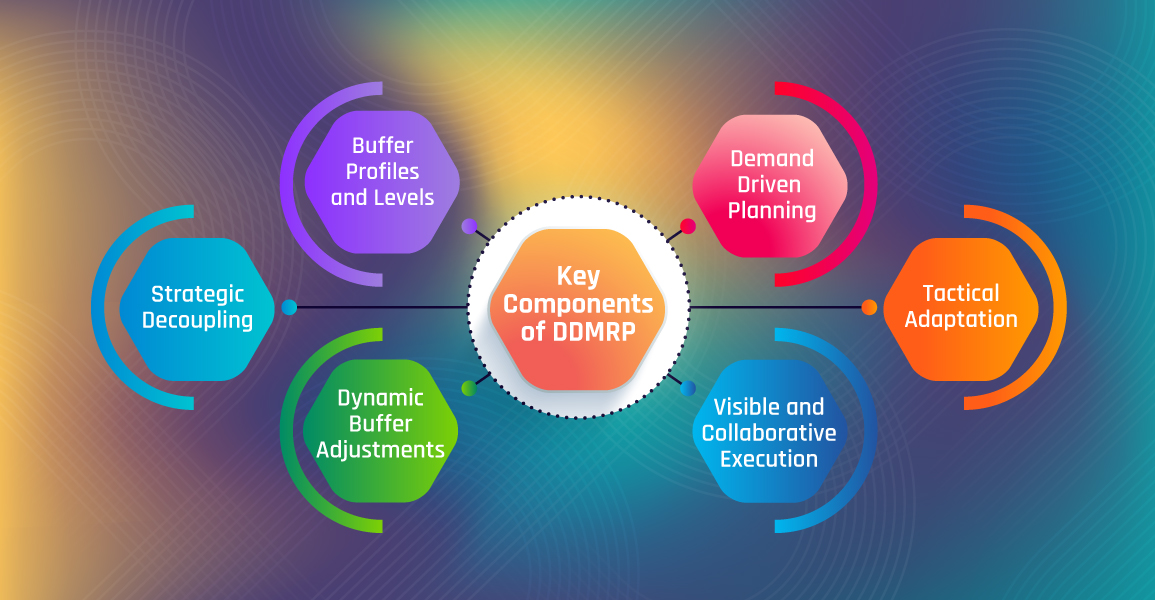

DDMRP focuses on six primary components:

- Strategic Decoupling: Strategic decoupling starts with determining the optimal placement of decoupling points within the supply chain. These points act as buffers to reduce demand signal distortion and ensure supply continuity during order generation and execution. Selecting decoupling points is a strategic decision that impacts customer lead times and inventory investment. DDMRP utilises six criteria to decide where these points should be placed in a specific environment.

- Buffer Profiles and Levels: Buffers must be appropriately sized to keep the decoupling points effective. In DDMRP, each decoupled item is assigned to a buffer profile—a set of settings applied to items with similar attributes such as lead time, product structure tier, and susceptibility to supply or demand variability. Buffer profiles simplify the management of large numbers of decoupled items across an organisation.

- Dynamic Buffer Adjustments: In a volatile, uncertain, complex, and ambiguous (VUCA) world, supply chains need to be adaptable. The third component of DDMRP allows buffer levels at decoupling points to adjust dynamically based on changes in an item’s properties, such as demand rate, lead time, and profile adjustments for planned or known events like promotions or seasonal activities. Many of these adjustments are automated in DDMRP-compliant systems.

- Demand Driven Planning: Demand driven planning involves applying unique supply order generation rules to the configured DDMRP model. These rules, known collectively as the net flow equation, are typically applied daily to all decoupled (buffered) positions. Dependent demand generated from these positions cascades down through lower levels in a process known as decoupled explosion.

- Visible and Collaborative Execution: DDMRP clearly distinguishes between planning and execution phases. The planning phase ends once an order recommendation is approved and converted to a scheduled receipt. DDMRP execution manages open orders against these scheduled receipts using two types of alerts: Buffer Status Alerts and Synchronisation Alerts. These alerts pinpoint potential flow blockages that could impact customer commitments or compromise buffer integrity.

- Tactical Adaptation: The final component of DDMRP involves managing the adaptation of the DDMRP model, as defined by the first three components, collectively known as the Master Settings. This adaptation cycle, driven by past performance and anticipated future activities, is called Demand Driven Sales and Operations Planning (DDS&OP). DDS&OP is vital for maintaining an effective DDMRP implementation and introduces key changes to conventional practices, such as eliminating the need for a master production schedule (MPS).

The Role of Cloud Computing in Supply Chain Management

Cloud Computing Defined

Cloud computing refers to the delivery of computing services—servers, storage, databases, networking, software, and more—over the internet (the cloud). These services provide faster innovation, flexible resources, and economies of scale.

Benefits of Cloud Computing

- Scalability: Cloud solutions can quickly scale up or down based on the needs of the business, providing flexibility to manage peak periods and slowdowns without the need for significant capital investment.

- Accessibility: With cloud computing, data and applications are accessible from anywhere with an internet connection, facilitating remote work and collaboration.

- Cost-Effectiveness: Cloud services often operate on a pay-as-you-go model, reducing the need for large upfront investments in IT infrastructure.

- Integration: Cloud platforms offer extensive integration capabilities with existing IT systems, streamlining operations and improving data flow.

- Security: Leading cloud providers invest heavily in security measures to protect data and ensure compliance with industry standards and regulations.

Implementing Cloud-Based DDMRP: Steps to Success

Assessing Readiness

Before embarking on the journey of implementing cloud-based DDMRP, it is crucial for organisations to assess their current readiness. This involves evaluating existing IT infrastructure, identifying key pain points in the supply chain, and understanding the specific requirements of their business. A thorough assessment will help in identifying the most suitable cloud service providers and DDMRP solutions that align with the organisation’s goals. It also provides a clear picture of the potential benefits and challenges that may arise during implementation. This preparatory step ensures that the organisation is well-positioned to leverage the capabilities of cloud-based DDMRP effectively.

Selecting the Right Cloud Service Provider

Choosing the right cloud service provider is a critical step in the implementation process. Organisations should look for providers that offer robust security measures, scalability, and seamless integration capabilities. Additionally, the provider should have a proven track record in supporting supply chain operations and be able to offer industry-specific solutions.

Key factors to consider when selecting a provider include:

- Security and Compliance: Data security and compliance are paramount concerns when adopting cloud-based solutions. Organisations must ensure that their chosen cloud provider adheres to industry standards and regulations, such as GDPR, HIPAA, or ISO 27001.

- Scalability and Flexibility: The ability to scale resources up or down based on demand.

- Support and Service Level Agreements (SLAs): Availability of round-the-clock support and clear SLAs.

- Cost Structure: Understanding the pricing model and ensuring it aligns with the organisation’s budget.

By thoroughly vetting potential providers, organisations can select a partner that will support their long-term goals and facilitate a smooth implementation.

Planning and Implementation

A successful implementation of cloud-based DDMRP requires careful planning and execution. This involves setting clear objectives, defining key performance indicators (KPIs), and establishing a detailed project plan. Key stakeholders from various departments, including IT, supply chain, and finance, should be involved in the planning process to ensure alignment and buy-in.

The implementation phase should include:

- Data Migration: Transferring existing data to the cloud platform while ensuring data integrity and security. This step is crucial to maintain continuity and accuracy in supply chain operations.

- System Integration: Integration is a critical aspect of implementing cloud-based DDMRP solutions. Organisations must ensure that the new system can seamlessly integrate with their existing IT infrastructure, including ERP, MRP, and other supply chain management systems. This integration is essential for maintaining data consistency and ensuring smooth operations.

- Training and Change Management: Providing comprehensive training to employees and stakeholders to ensure they are comfortable with the new system. Effective change management strategies can facilitate a smoother transition and increase user adoption.

- Testing and Validation: Conducting thorough testing to identify and resolve any issues before going live. This step helps to mitigate risks and ensure that the system functions as expected in a live environment.

Continuous Improvement

The implementation of cloud-based DDMRP is not a one-time project but an ongoing process of continuous improvement. Organisations should regularly monitor performance, analyse data, and make necessary adjustments to optimise supply chain operations. This involves leveraging the analytics and reporting capabilities of the cloud platform to gain insights and drive continuous improvement initiatives.

Regular reviews and updates of the system, based on feedback and performance metrics, can help in maintaining the system’s effectiveness and adapting to changing business needs.

Measuring Success

To measure the success of cloud-based DDMRP implementation, organisations should track key performance indicators (KPIs) that align with their business objectives. These KPIs provide a quantifiable way to evaluate the effectiveness of the system and identify areas for continuous improvement. Some of the critical KPIs to consider include:

- Inventory Turnover: Inventory turnover measures the rate at which inventory is used and replenished. A higher turnover rate indicates efficient inventory management, as products are moving quickly through the supply chain. Monitoring this KPI helps organisations minimise holding costs and reduce the risk of obsolescence. By leveraging cloud-based DDMRP, companies can achieve optimal inventory levels, ensuring that they have the right amount of stock at the right time.

- Order Fulfilment Time: Order fulfilment time tracks the time taken to fulfil customer orders from receipt to delivery. Reducing this time is crucial for improving customer satisfaction and maintaining a competitive edge. Cloud-based DDMRP provides real-time visibility into inventory levels and demand patterns, enabling faster and more accurate order processing. By continuously monitoring and optimising order fulfilment times, organisations can enhance their responsiveness to customer needs.

- Stockouts and Overstock Situations: The frequency and impact of stockouts and overstock situations are critical indicators of supply chain efficiency. Stockouts can lead to lost sales and diminished customer trust, while overstock situations result in increased holding costs and potential waste. Cloud-based DDMRP helps balance supply and demand by dynamically adjusting buffer levels. Tracking this KPI allows organisations to fine-tune their inventory strategies, reducing both stockouts and excess inventory.

- Customer Satisfaction: Customer satisfaction is a vital KPI that reflects the effectiveness of the supply chain in meeting customer expectations. Feedback and satisfaction levels related to product availability and delivery times provide valuable insights into areas for improvement. Cloud-based DDMRP enhances visibility and collaboration across the supply chain, leading to more reliable and timely deliveries. By regularly collecting and analysing customer feedback, organisations can ensure that their supply chain operations align with customer needs and preferences.

- Cost Savings: While cloud-based solutions offer numerous benefits, it’s essential to consider the cost implications. Organisations should evaluate the total cost of ownership (TCO) of cloud-based DDMRP solutions compared to traditional on-premises systems. This evaluation should include not only the direct costs of the cloud service but also the potential savings in terms of reduced hardware investments, maintenance, and IT personnel.

By regularly tracking these KPIs, organisations can assess the impact of cloud-based DDMRP on their supply chain operations and make data-driven decisions to drive further improvements. This continuous monitoring ensures that the implementation remains aligned with organisational goals and delivers the anticipated benefits.

Future Trends and Developments in Cloud-Based DDMRP

Artificial Intelligence and Machine Learning

The integration of artificial intelligence (AI) and machine learning (ML) with cloud-based DDMRP solutions holds tremendous potential for further enhancing supply chain operations. AI and ML can analyse vast amounts of data to identify patterns and trends, enabling more accurate demand forecasting and buffer adjustments.

For example, AI algorithms can predict demand surges based on historical sales data, social media trends, and other external factors. This predictive capability allows companies to proactively adjust their inventory positions and production schedules, reducing the risk of stockouts and overstock situations.

Internet of Things (IoT)

The Internet of Things (IoT) is another technology that can complement cloud-based DDMRP solutions. IoT devices, such as sensors and RFID tags, can provide real-time data on inventory levels, shipment status, and environmental conditions. This data can be integrated into the cloud platform, providing a comprehensive view of the supply chain.

For instance, IoT-enabled sensors can monitor the temperature and humidity of perishable goods during transit, ensuring that they are stored and transported under optimal conditions. This visibility allows companies to take corrective actions promptly, minimising the risk of product spoilage and improving overall supply chain efficiency.

Blockchain Technology

Blockchain technology offers a secure and transparent way to track and verify transactions across the supply chain. By integrating blockchain with cloud-based DDMRP solutions, companies can enhance traceability and accountability.

For example, blockchain can provide a tamper-proof record of product movements from the manufacturer to the end consumer. This traceability ensures that all parties have access to accurate and verifiable information, reducing the risk of fraud and ensuring compliance with industry regulations.

Conclusion

The integration of cloud-based solutions with DDMRP has the potential to revolutionise supply chain operations. By leveraging the scalability, flexibility, and real-time data accessibility of cloud computing, organisations can enhance their supply chain visibility and responsiveness. The benefits of cloud-based DDMRP solutions extend beyond operational efficiency, contributing to cost savings, improved collaboration, and increased competitiveness in the digital age.

As organisations continue to navigate the complexities of the modern supply chain, the adoption of cloud-based DDMRP solutions will be a critical enabler of success. By considering key factors such as cost-effectiveness, integration, and security, companies can make informed decisions and harness the full potential of these transformative technologies. The future of supply chain management lies in the seamless integration of advanced methodologies like DDMRP with cutting-edge cloud technologies, paving the way for a more agile, resilient, and responsive supply chain.

Learn how cloud-based solutions can elevate your DDMRP implementation. Get in touch today!