Digital Twins: The Future of Supply Chain Innovation

November 12, 2021

Highlights from the SCE 2021 Supply Chain Event in Paris

November 26, 2021Sharing knowledge about Demand Driven MRP is fundamental to moving the industry forward. More leaders adopting Demand Driven methodology means greater efficiency, cost savings, and resilience for everyone. After all, no supply chain exists in isolation.

That’s why Patrick Rigoni believes in sharing his expertise as a Demand Driven Institute Master Instructor and DDMRP practitioner. His latest collaboration with Advance Operations Management School is a prime example. In partnership with Daniele Meldolesi, Founding Partner at Advance, Patrick Rigoni has published a white paper titled, “How Demand Driven MRP improves corporate performance in terms of Service, Inventory and Lead Time.” The publication is a “Snapshot” produced by Advanced Supply Chain Solutions, the division of Advance that provides consultancy services in Procurement, Supply Chain Management, Lean Six Sigma and DDMRP.

Within the white paper are nuggets of wisdom about implementing DDMRP in a real-world setting. With forecast accuracy such a key ingredient to successful supply chain planning, it’s essential that professionals in the industry learn how to accurately predict and plan for the long-haul. DDMRP provides the skill set supply chain managers need to make it happen.

The end result is a deep dive into DDMRP in a digestible format, perfect for both students and seasoned supply chain leaders who are seeking insight from an expert. The Snapshot focuses on four key themes:

- The explanation of what Demand Driven MRP is and how it works

- The 3 essential principles of DDMRP

- The role of forecasts in Demand Driven methodology

- Tips and guidelines for successful implementation of DDMRP.

Curious how Patrick Rigoni initiated this partnership with Advance, which has branches across Italy and Switzerland? If you’d like a sneak peek into the inner workings of the process and further insight from the co-author of this brand new white paper, you’ve come to the right place. Keep reading to learn more about Patrick Rigoni’s recent work.

QUESTION: How did the collaboration start with Advance Operation Management School and how long did it take to create the white paper?

RIGONI: We started the collaboration two years ago when Advance Operation Management School was looking for an accredited DDI instructor that could teach the DDP and DDL curriculum in Italian and could also manage DDMRP implementation projects for some of their clients.

QUESTION: What is the role of forecast in Demand Driven that was mentioned in the white paper?

RIGONI: Contrary to what people sometimes hear, forecasts have an important place in DDMRP. The question is not whether you should use forecast or not, but in which time frame and for what purpose. In DDMRP forecasts are NOT used in the operational time frame to generate (re-)supply orders. Forecasts are used in longer time frames (tactical and strategic) to calculate optimal buffer sizes and plan for future capacity, space, working capital and labour requirements.

QUESTION: Today, DDMRP is applied successfully to various industrial and distribution sectors, as well in retail shops. This method aims at reducing signal variations of demand and supply through the strategic positioning of buffers in the supply chain key points. Can you give us an example or case study of a recent project that you worked with where DDMRP was applied?

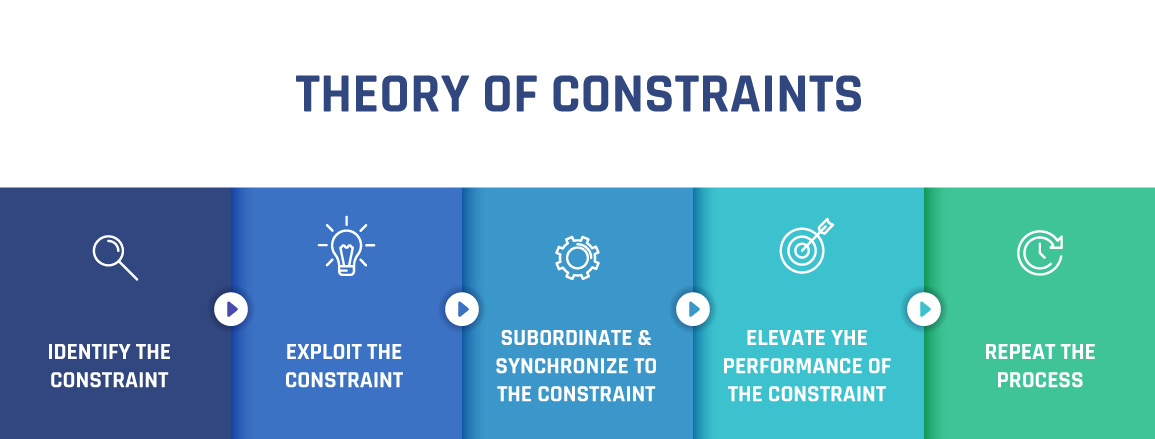

RIGONI: Lately we worked with a medium sized Italian company to replace their current planning approach from a ToC methodology (Theory of Constraints) to DDMRP. This is an interesting case study because the starting point, in this case, was not traditional MRP like for most other companies but rather something that is like a precursor of DDMRP. The difference is that DDMRP is much more versatile and provides the planners with a more exhaustive toolkit and planning functionalities.

Patrick Rigoni is available to consult with you and your team about applying DDMRP principles to effect change across the supply chain. Get in touch today to learn how to build resilience, thrive in an uncertain global market, and maximize efficiency.

Want to know more about how to manage your supply chain business? Book a free consultation with Patrick Rigoni today!