Leveraging IoT for Enhanced DDMRP Execution in Inventory Management 4.0

August 30, 2024

The Role of DDMRP in Streamlining Supplier and Customer Communication

September 13, 2024In today’s interconnected global marketplace, the ability to collaborate effectively across the supply chain is more crucial than ever. Supply chain partners must work in unison, sharing information and resources seamlessly to ensure the smooth flow of goods and information. However, traditional supply chain planning methods, often reliant on outdated forecasting models and siloed information, struggle to meet the challenges of today’s dynamic and volatile markets. These limitations can result in stockouts, overstocks, inefficiencies, and strained relationships between partners.

Demand Driven Material Requirements Planning (DDMRP) emerges as a beacon of hope, offering a revolutionary approach to supply chain management that places collaboration at its core. By prioritising real-time visibility, agility, and demand driven planning, DDMRP empowers businesses to transcend traditional constraints and forge a more collaborative and resilient supply chain.

The Current State of Supply Chain Collaboration

Challenges and Pain Points in Traditional Collaboration

Traditional supply chain collaboration faces numerous challenges that hinder its effectiveness. One major pain point is the reliance on forecasts, which, despite sophisticated models, often fall short of accurately predicting demand. These inaccuracies create a ripple effect, leading to mismatches between supply and demand. Excess inventory ties up capital and storage space, while shortages result in missed sales and dissatisfied customers.

Another obstacle is the siloed nature of information within organisations. Each department or partner may have its own data and systems, making it difficult to share information and gain a comprehensive view of the supply chain. This lack of transparency creates blind spots, hindering collaboration and proactive decision-making.

Furthermore, traditional planning methods are often reactive, based on historical data. While valuable, past trends may not reflect the current market dynamics. Businesses find themselves constantly playing catch-up, reacting to changes rather than anticipating them. This reactive approach can result in missed opportunities, increased costs, and a loss of competitive advantage.

The Need for a Demand Driven Approach

The rapid pace and inherent unpredictability of the business environment necessitate a shift towards a demand driven approach to supply chain management. Businesses can no longer afford to rely solely on forecasts, which are often outdated the moment they are created. Instead, they need the ability to sense and respond to changes in real-time, aligning their operations with actual demand signals.

This agility demands a fundamental paradigm shift. The old model of relying on historical data and static forecasts must give way to a dynamic, responsive approach that prioritises collaboration, information sharing, and proactive decision-making. By harnessing real-time data and insights, businesses can anticipate shifts in demand, adjust their inventory levels, and optimise production schedules.

This demand driven approach fosters a more resilient and adaptable supply chain, capable of navigating the complexities of the modern marketplace. It empowers businesses to meet customer needs efficiently, minimise waste, and ultimately, achieve a competitive advantage in an increasingly demanding world.

Introducing DDMRP: A Solution for Enhanced Collaboration

DDMRP is a methodology that places actual demand at the heart of supply chain planning. It utilises strategic inventory positioning, buffer profiles and levels, dynamic adjustments, and visible, collaborative execution to create a demand driven and responsive supply chain.

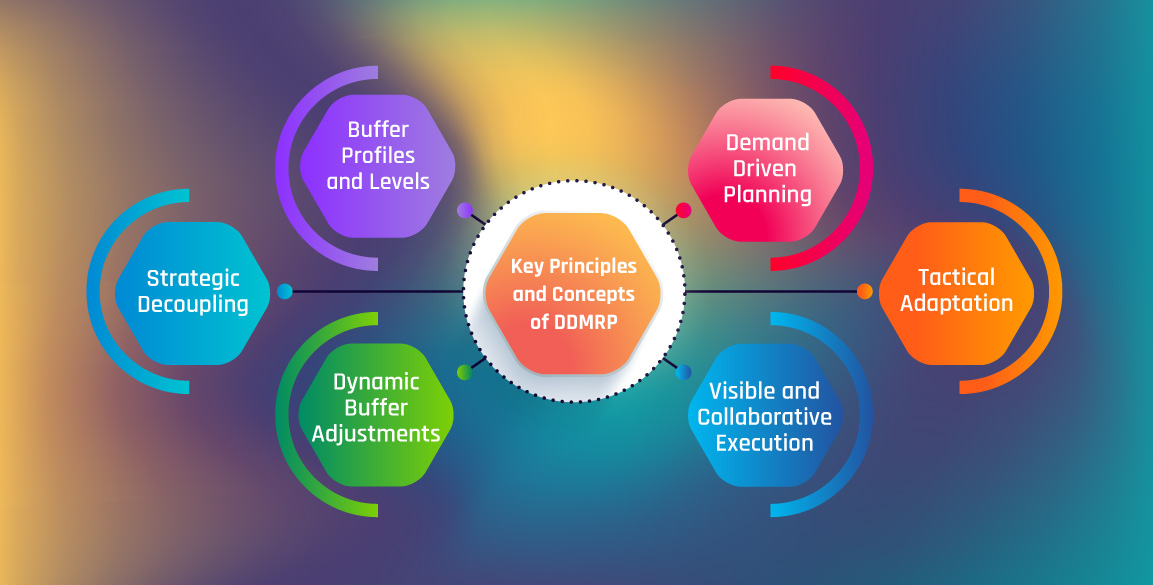

Key Principles and Concepts of DDMRP

- Strategic Decoupling: The foundation of DDMRP lies in identifying strategic decoupling points within the supply chain. These points act as buffers, safeguarding against fluctuations in demand and ensuring supply continuity. The choice of decoupling points is pivotal, influencing both customer lead times and inventory levels.

- Buffer Profiles and Levels: Buffers are crucial to ensure decoupling points remain effective. Each decoupled item is assigned a buffer profile in DDMRP, a collection of settings applied to similar items with comparable characteristics like lead times, product tiers, and susceptibility to demand or supply variations. Buffer profiles simplify the management of numerous decoupled items across the organisation.

- Dynamic Buffer Adjustments: DDMRP allows buffer levels at decoupling points to adapt based on real-time factors such as demand rates, lead times, and profile changes. These adjustments can even consider planned events like promotions or seasonal shifts. Many of these adaptations are automated in systems designed for DDMRP.

- Demand Driven Planning: The operational aspect of DDMRP involves applying unique supply order generation rules, known as the net flow equation, to the configured DDMRP model. This equation is usually executed daily on all decoupled positions. Dependent demand stemming from these positions is then transferred down to the next buffered position in a process called decoupled explosion.

- Visible and Collaborative Execution: DDMRP distinguishes between planning and execution. Planning concludes when order recommendations are approved and converted to scheduled receipts. Execution then manages open orders against these receipts, using Buffer Status Alerts and Synchronisation Alerts to highlight potential flow disruptions that could impact customer commitments or buffer integrity.

- Tactical Adaptation: The final aspect of DDMRP focuses on adjusting the DDMRP model’s master settings (the first three components). This adaptation cycle considers both past performance and anticipated future activity. This process, called Demand Driven Sales and Operations Planning (DDS&OP), is vital for maintaining an effective DDMRP implementation.

How DDMRP Enables a Collaborative Ecosystem

DDMRP fosters a collaborative ecosystem within the supply chain by dismantling the traditional barriers of information silos. It achieves this by providing all stakeholders with real-time access to critical data, including demand signals, inventory levels, and buffer statuses. This transparent flow of information establishes a foundation of trust, enabling partners to proactively address potential issues and collectively streamline the movement of goods and information.

The dynamic adjustments and demand driven planning inherent in DDMRP further enhance collaboration. By focusing on actual demand rather than relying solely on forecasts, partners can respond swiftly to market fluctuations. This agility minimises disruptions and fosters a sense of shared responsibility in meeting customer needs. With everyone aligned and equipped with the latest information, the supply chain becomes a unified network capable of responding effectively to the ever-changing demands of the market.

Transforming Collaboration: The Impact of DDMRP

Demand Driven Material Requirements Planning (DDMRP) represents a significant evolution in the way supply chains operate, driving a transformative shift from isolated, disjointed systems to a more integrated and cohesive approach.

- From Isolation to Integration: It provides all partners with a unified, real-time view of operations, allowing for a shared understanding that empowers more informed decision-making. By eliminating guesswork and enabling access to the most current data, DDMRP facilitates a proactive approach to problem-solving, ensuring that decisions are based on accurate and timely information.

- Agility and Adaptability: The traditional supply chain model often necessitated a reactive approach to planning, where companies scrambled to adapt to market changes after they occurred. This reactive stance often led to inefficiencies, as supply chains struggled to keep up with fluctuating demand. DDMRP, however, changes the game by enabling a more agile and adaptable supply chain. Through enhanced communication and coordination, partners can respond swiftly and decisively to changes in demand, minimising disruptions. The real-time data and shared visibility provided by DDMRP create an environment where agility is not just an advantage but a necessity. This adaptability ensures that supply chains remain resilient and capable of navigating the uncertainties inherent in today’s markets.

- Empowerment and Accountability: One of the key benefits of DDMRP is its ability to empower all participants within the supply chain. Rather than simply providing information, DDMRP equips partners with the tools and insights needed to take ownership of their specific roles. This empowerment fosters a sense of responsibility, encouraging all participants to be proactive in identifying and addressing potential issues before they escalate. The result is a culture of continuous improvement, where everyone is focused on the common goal of maintaining a healthy and efficient supply chain. This sense of accountability drives better performance and ensures that all partners are aligned in their efforts to optimise the supply chain.

- Trust as the Bedrock: At the heart of DDMRP’s collaborative model is the concept of trust. By promoting transparency and open communication, DDMRP creates an environment where trust and mutual respect can flourish. This shared sense of purpose leads to stronger relationships among supply chain partners, as everyone is invested in the success of the entire ecosystem. The collaboration fostered by DDMRP not only helps partners achieve their shared goals but also lays the foundation for long-term, sustainable growth. As trust is built over time, the supply chain becomes more resilient and capable of withstanding challenges, ensuring that all parties benefit from the collective success.

Embarking on the DDMRP Journey

Navigating the Implementation Process

Implementing DDMRP is not simply a matter of flipping a switch; it requires a well-structured plan and a dedicated commitment to transforming your supply chain. The journey begins with a comprehensive assessment of your current processes, identifying areas of strength and weakness. This introspection allows you to pinpoint the specific pain points that DDMRP can address, tailoring the implementation to your unique needs.

Once you have a clear understanding of your current state, it’s crucial to engage stakeholders from across the supply chain. This includes everyone from suppliers and manufacturers to distributors and retailers. Building consensus and securing buy-in from all parties is essential for a successful DDMRP implementation. Open communication and collaboration are key to ensuring that everyone understands the benefits of DDMRP and is on board with the necessary changes.

Addressing Potential Challenges

While the benefits of DDMRP are undeniable, the implementation process is not without its challenges. One common hurdle is data integration. DDMRP relies on accurate and timely data from various sources across the supply chain. Ensuring data integrity and seamless integration between systems can be complex, requiring investment in technology solutions and careful data management practices.

Another challenge is change management. Implementing DDMRP often involves significant changes in processes, roles, and responsibilities. It’s crucial to anticipate and address resistance to change by providing comprehensive training and education to employees. Clear communication and ongoing support will help ease the transition and ensure that everyone understands their role in the new demand driven environment.

Finally, fostering a collaborative culture is essential for DDMRP’s success. While DDMRP promotes collaboration, it requires a shift in mindset and a willingness to share information openly. Building trust, establishing clear communication channels, and aligning objectives across the supply chain may take time and effort. However, the long-term benefits of a collaborative ecosystem far outweigh the initial challenges.

The Future of Supply Chain Collaboration: DDMRP’s Role

The future of supply chain collaboration is being shaped by the rapid adoption of Demand Driven Material Requirements Planning (DDMRP). As supply chains become increasingly complex and globalised, the need for more integrated and responsive systems is paramount. DDMRP is poised to lead this transformation by offering a framework that not only enhances collaboration but also ensures that supply chains are more resilient, adaptable, and efficient.

The benefits of DDMRP-driven collaboration extend far beyond short-term gains. By building a more agile and responsive supply chain, businesses can achieve sustainable success in the long run. They can adapt to changing market conditions, mitigate risks, and seize opportunities with confidence. DDMRP’s focus on demand driven planning ensures that resources are allocated efficiently, reducing waste and minimising costs. This not only improves profitability but also contributes to a more sustainable and environmentally responsible supply chain.

DDMRP is set to be a cornerstone in the future of supply chain collaboration, driving the evolution towards more integrated, agile, and transparent systems. As businesses continue to navigate a rapidly changing landscape, the adoption of DDMRP will be instrumental in creating supply chains that are not only more efficient but also better equipped to handle the challenges of the future.

Conclusion

In the face of an increasingly complex and uncertain global landscape, DDMRP offers a beacon of hope. It empowers businesses to navigate challenges, seize opportunities, and build a supply chain that is not only efficient but also adaptable and resilient. By embracing the principles of DDMRP and prioritising collaboration, organisations can forge a path towards a future where supply chains are not just functional, but truly collaborative and thriving.

Discover how DDMRP can enhance collaboration across your supply chain