DDMRP in Aerospace Supply Chain Management

April 1, 2022

DDMRP in Telecom and Electronic Supply Chain Management

April 22, 2022For more than half a century, material requirements planning (MRP) has formed the backbone of the building and supply chain industry. MRP is a calculating engine that determines which materials and components to order, how many are necessary when required, and when activity must begin to complete the task so that goods are ready by the estimated completion date.

The problem with MRP is that it forecasts the future based on past results, which are not accurate as there are some unforeseen circumstances like late payment of the receipt, having quality issues of the product, which makes the forecast difficult. So what can be the better alternative to MRP? The answer to this question is Demand Driven Material Requirement Planning(DDMRP).

What is DDMRP?

Demand Driven Material Requirement Planning (DDMRP) is an advanced planning process used by building and construction supply chain industries to ensure that commodities flow smoothly through the entire supply chain. It’s a necessary first step in linking operations to changing market demand — and then using that connection to generate innovation and agility.

How does the DDMRP work?

DDMRP triggers inventory orders based on sales and consumption data rather than projections. DDMRP ensures you always have the right products in the right location — and in the appropriate amount — by timing materials to market demand. It’s a simple system that improves service, lead times, and inventory levels while increasing agility. It’s also a vital component of the Demand Driven Adaptive Enterprise (DDAE), a management approach that allows businesses to recognise and respond to complex, turbulent markets.

DDMRP isn’t just a better method to plan and manage your supply chain; it’s also a better way to plan and manage your business. It’s a tried-and-true strategy for increasing agility and innovation in your business.

Why do the building and construction supply chain need DDMRP?

The building and construction supply chain are often unable to manage their inventory. As a result, they face shortages of materials and cannot deliver the product to their customers at the right time. This is the real issue, which is caused by forecast imperfection and supply chain inconsistencies, such as late payments, extra scrap, quality issues, and faulty records, to name a few.

While manufacturers recognise that unpredictability cannot be avoided entirely, they aim to find a solution to reduce excess inventory and avoid shortages. DDMRP is a supplement to regular MRP that accomplishes this.

How can DDMRP help the building and construction supply chain industries?

In terms of customer service, the users are not consistently achieving 97 to 100% on-time fill rate performance, which has ultimately improved the customer experience. Not only that, but the typical inventory size has also reduced to around 30 to 45 per cent. DDMRP has also solved the problem of excess lead time and has reduced the timing by over 80% in several industry segments. The clients also successfully reduce the cost as the expenditure related to expedite activity and false signals are almost removed from the system.DDMRP has also made the entire process so easy and intuitive that planners are now able to prioritise their workflow, and they no longer have to fight over the conflicting messages of the MRP.

Building and Construction supply chain companies that implemented DDMRP

-

CERAMFIX

Ceramfix was established in 1993. It has a production capacity of 50 tons per month. The main problem was that they merely forecasted their future requirements by product families only. This resulted in the lack of space, and thus, they needed to expand their warehouse. Therefore, Ceramfix decided to implement DDMRP through strategic inventory management in their company. Earlier, they used to have monthly purchase orders, which meant smaller prices for the product. Also, the production order was based on forecasts that led to big production orders. The DDMRP implementation changed it to weekly purchase orders and smaller production orders as the production was based on the actual demand. They also included central planning so that there is a steady demand from the customers and result in maximum profitability. They also implemented DDMRP in many steps of the supply chain: raw materials, purchasing, production, distribution, finished products, and intermediate products.

The main results that Ceramfix saw after dump implementation were:

- The cumulative lead time was reduced to 28 days compared to 35 days before. This led them to save $385k.

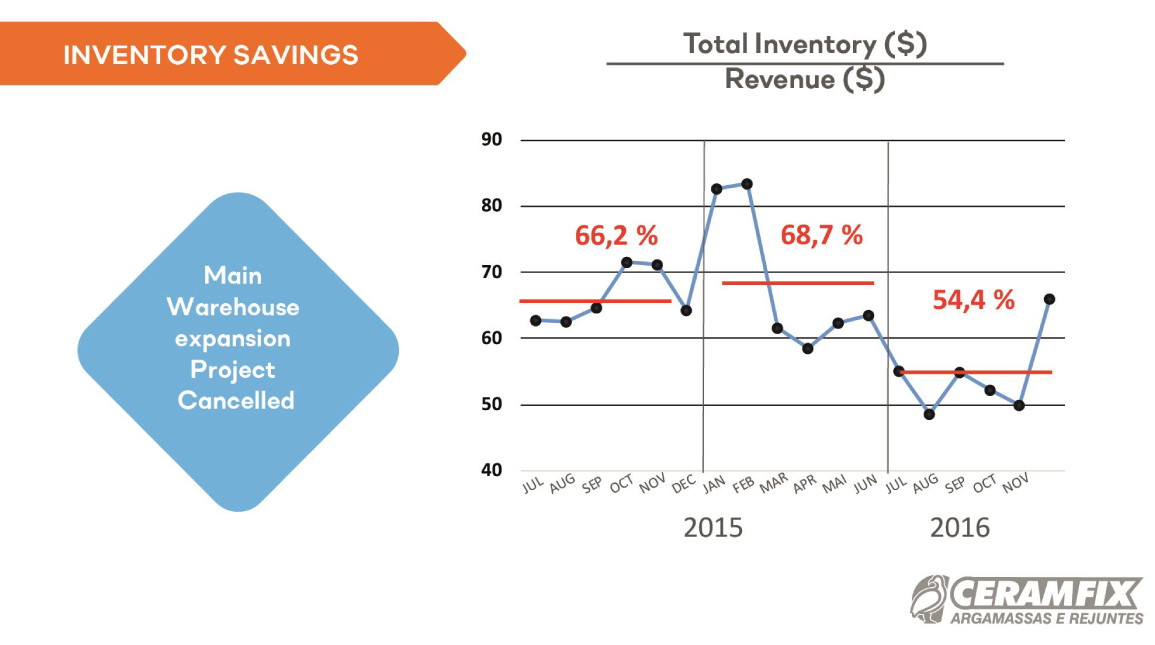

- The total inventory per revenue reduced to 54.4% in September 2015 compared to 66.2% in October 2014. This solved the main space problem as it led to the cancellation of the main warehouse expansion project.

- The customer service level increased to 99.5% from 98%.

- Stockout was reduced to 96.5% as compared to 97.6%.

-

ETEX

ETEX aspires to improve its customers’ living standards by revolutionising the construction industry by introducing compelling, lightweight solutions and building a name in the industry for its impeccable performance. ETEX is passionate about excelling at supply chain standards and delivering the best project to the organisation. Their leadership principle, “Pause to reflect and learn”, has helped the company be innovative and create better values and results in the marketplace.

Why did ETEX decide to go with DDMRP?

The high cost for the strategic ROMaterial, plus no methodology to keep the planning process harmonised made the sustenance difficult for ETEX. At the same time, there was a wide variety of local contacts profiles, which led to a disconnection in the flow of information and an unharmonised frequency of stock orders maintenance, which worsened the problem.

As soon as the company decided to implement DDMRP, it saw a reduction of 15% in the stock value of the strategic raw materials for the company. Not only that, but this implementation also helped the client get more visibility on what they should prioritise. In the business world, if you prioritise the right things at the right moment, you get to save a lot of time, and the same happened with ETEX, as they were able to save 20% of the time on the raw materials planner’s tasks.

Conclusion

DDMRP solves the supply order forecast error by helping the company get aligned with actual market requirements and make better-informed decisions with the correct information at their fingertips. This demand-driven material requirement planning process helps you collect all the necessary items of strategic importance for your business by accurately forecasting the sales, which ultimately helps you generate the right supply plans.

As discussed in the above case studies, it makes a lot of sense that the supply chain companies can use DDMRP training to excel in the executions and make informed decisions, rather than blind guessing. In the traditional method, the building and construction company had to manage an unorganised and unplanned inventory which either led to overcrowding of space with unnecessary items during low sales cycles or an undersupply of strategic raw materials during crucial times.

This unmanaged and unorganised system made the sheer existence and sustenance of the companies mentioned above difficult. However, DDMRP has come up to solve this issue by allowing the companies to fill the inventory based on the demand in the market.

To know more about DDMRP from Patrick Rigoni, get the latest information in our DDMRP Page.