Continuous Improvement through DDMRP: A Resilience Perspective

October 27, 2023

The Role of Technology in DDMRP Optimization

November 24, 2023In the rapidly evolving and dynamic landscape of modern business, effective supply chain management stands as a pivotal determinant of an organisation’s triumph. Enterprises are persistently in pursuit of innovative methods to enhance their supply chain operations, aligning them with customer demands while concurrently optimising costs and efficiency. One such formidable approach that has surged in popularity in recent years is Demand Driven Material Requirements Planning (DDMRP). DDMRP underscores the significance of real-time data analytics as a driving force behind the relentless enhancement of the supply chain. Within the confines of this article, we will delve into the strategies through which enterprises can harness the potential of data analytics and valuable insights to steer continuous amelioration within their supply chains by embracing DDMRP. We will dissect the essential data types and performance metrics that form the bedrock of DDMRP prosperity, encompassing demand data, lead times, and inventory levels.

Understanding DDMRP: A Quick Overview

Before delving deeper into the realm of DDMRP analytics, it’s prudent to provide a succinct overview of what DDMRP entails and understand why it has gained prominence as a preferred methodology in supply chain management. Demand Driven Material Requirements Planning (DDMRP) represents a groundbreaking approach to the intricacies of inventory and production management, pioneered by the Demand Driven Institute. It marks a notable departure from traditional, forecast-centric Material Requirements Planning (MRP) systems that frequently result in the undesirable consequences of overstocked inventories or distressing stockouts.

DDMRP takes a fundamentally different path; it hinges on real-time, actual demand signals. This shift in focus empowers organisations with heightened responsiveness and adaptability to meet the ever-evolving requirements of their customers. The crux of this methodology is rooted in data-driven insights, enabling the establishment of optimal inventory levels, the dynamic fine-tuning of production schedules, and a significant reduction in lead times. DDMRP’s core tenets encompass strategic decoupling, precision buffer sizing, and demand-centric planning. It’s precisely these foundational principles that render DDMRP an organic fit for harnessing data analytics as a catalyst for perpetual enhancement.

The Role of Data in DDMRP Success

Data is the lifeblood of any DDMRP implementation. To effectively leverage DDMRP for continuous improvement, organisations need to collect, analyse, and act upon various types of data. Here are some of the key data components in DDMRP:

Demand Data

Demand data is at the heart of DDMRP. Accurate and up-to-date demand data helps organisations understand what products or materials are needed, when they are needed, and in what quantities. Collecting data on historical demand patterns, current customer orders, and market trends allows organisations to make informed decisions about their production and procurement processes. Data analytics can help identify seasonality, trends, and variations in demand, which are crucial for buffer sizing and replenishment decisions.

Lead Time Data

Lead time data is another critical element for DDMRP success. Lead time refers to the time it takes for an order to be fulfilled, from the moment it’s placed to when it’s received. Inaccurate lead time data can lead to unnecessary stock outs or excessive inventory. Data analytics can help organisations assess lead times accurately by tracking past lead times and considering variations due to factors like supplier performance or transportation delays. This data allows organisations to set appropriate buffer levels to safeguard against supply chain disruptions.

Inventory Levels

Inventory management is a cornerstone of DDMRP, and it heavily relies on data related to inventory levels. Maintaining the right inventory levels can be a daunting task, but with the help of data analytics, organisations can fine-tune their inventory management. By monitoring inventory turnover rates, carrying costs, and buffer stock levels, companies can optimise their inventory to minimise holding costs while ensuring they can meet customer demand.

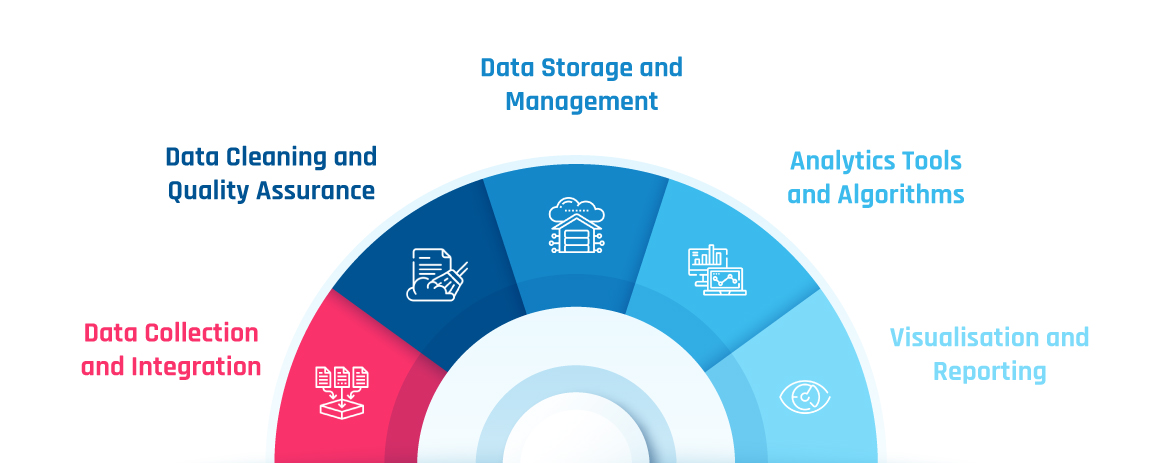

The Analytics Framework for DDMRP

With the importance of data in DDMRP established, it’s time to explore how organisations can create an analytics framework to drive continuous improvement. This framework should encompass several key elements:

Data Collection and Integration

The first step in building a DDMRP analytics framework is collecting relevant data from various sources within the supply chain. This includes data from the ERP system, point-of-sale systems, production data, supplier data, and more. Integrating these diverse data sources is essential to create a comprehensive view of the supply chain.

Data Cleaning and Quality Assurance

Data quality is paramount. Inaccurate or inconsistent data can lead to flawed analytics and poor decision-making. Data cleaning and quality assurance processes should be in place to eliminate duplicates, correct errors, and ensure data accuracy. Robust data governance practices can help maintain data quality over time.

Data Storage and Management

Once data is collected and cleaned, it needs to be stored and managed effectively. Data warehouses or cloud-based solutions can be used to store historical and real-time data. An effective data management strategy includes data archiving, backup, and access controls.

Analytics Tools and Algorithms

The heart of any DDMRP analytics framework lies in the analytics tools and algorithms used to extract insights from the data. Advanced analytics techniques, such as machine learning and predictive modelling, can be applied to forecast demand, optimise buffer levels, and improve lead time accuracy.

Visualisation and Reporting

Data is only valuable when it can be transformed into actionable insights. Visualisation tools and dashboards can help supply chain professionals and decision-makers interpret the data. These tools make it easier to identify trends, anomalies, and areas for improvement. Regular reporting on key performance indicators (KPIs) is essential for monitoring the effectiveness of DDMRP strategies.

Continuous Improvement with DDMRP Analytics

With the right data and analytics framework in place, organisations can drive continuous improvement within their supply chains using DDMRP. Here are some key areas where data analytics can make a significant impact:

Demand Forecasting

Accurate demand forecasting is crucial for ensuring that inventory levels are aligned with customer demand. DDMRP analytics can analyse historical demand patterns and incorporate external factors such as market trends and seasonality to create more reliable demand forecasts. Continuous monitoring and adjustment of demand forecasts help organisations reduce stockouts and overstock situations.

Buffer Sizing

Buffer sizing is a core concept in DDMRP, and it relies heavily on data analytics. By analysing historical demand, lead time variations, and demand variability, organisations can determine the appropriate buffer sizes for different items in their inventory. Data-driven buffer sizing ensures that companies maintain the right amount of safety stock to mitigate supply chain disruptions without overinvesting in inventory.

Supplier Performance

DDMRP analytics can be used to assess and monitor supplier performance. By analysing data on on-time deliveries, lead times, and quality issues, organisations can identify areas where suppliers may need improvement. Data insights can drive negotiations and collaboration with suppliers to ensure a more reliable and responsive supply chain.

Lead Time Reduction

Analysing lead time data can help organisations identify bottlenecks and inefficiencies in their supply chain processes. With this information, they can implement strategies to reduce lead times, which, in turn, allows for more agile and responsive supply chain operations. Data-driven lead time reduction can significantly improve customer satisfaction by reducing wait times.

Inventory Optimization

DDMRP analytics can continuously evaluate inventory levels to identify excess inventory or shortages. By monitoring inventory turnover rates, carrying costs, and buffer levels, organisations can optimise their inventory and reduce holding costs. This not only frees up working capital but also ensures that the right products are available when customers need them.

Case Studies: Real-World Success Stories

To better understand the practical applications of DDMRP analytics, let’s explore a few real-world case studies of organisations that have harnessed data for continuous improvement in their supply chains:

Case Study 1: Louis Vuitton

Louis Vuitton, a renowned fashion brand, successfully implemented Demand Driven Material Requirements Planning (DDMRP) in its supply chain, leading to substantial benefits. The adoption of DDMRP has significantly enhanced inventory visibility and reduced stockouts. Notably, Louis Vuitton achieved a remarkable improvement in inventory turnover and a reduction in the volume of stock held at any given time, resulting in a more efficient and streamlined supply chain. DDMRP allowed Louis Vuitton to be more agile and responsive to market changes, ultimately improving communication and information flow within the company.

The implementation process involved a collaborative effort with Anaplan and a hackathon at an Information Technology School in Paris. Students devised a supply chain model rooted in DDMRP principles, fostering responsiveness to customer demands. Louis Vuitton started utilising DDMRP in its supply chain in 2013, leading to increased inventory accuracy, reduced stockouts, and enhanced customer service.

The benefits Louis Vuitton experienced since adopting DDMRP are substantial, including a 30% reduction in inventory levels while ensuring product availability, and delivery time improvements of up to 50%. DDMRP has enabled Louis Vuitton to become more agile, improve information flow, reduce lead times, and enhance customer service.

For other fashion brands, DDMRP offers several advantages. It can improve forecasting and inventory management, streamline supplier relationships, enhance production planning, reduce order management costs, and maintain higher profit margins. By leveraging DDMRP, fashion brands can achieve a more efficient and cost-effective supply chain, allowing them to respond swiftly to market fluctuations and ensure customer satisfaction while protecting their bottom line.

Case Study 2: BSH

BSH, facing various supply chain challenges, adopted Demand Driven Material Requirements Planning (DDMRP) to revamp its supply chain management. The company had been grappling with issues like supplier problems, disruptions, bottlenecks, and quality concerns. In response, BSH shifted its focus to the actual market demand, scrutinising fluctuations driven by seasonality and short-term demands, departing from reliance on traditional MRP forecasts. They introduced a direct-to-consumer distribution channel and prioritised customer-centricity. By transitioning to a pull-based approach that decoupled planning and execution and employing segmentation, BSH achieved more stable material flow. They followed a five-step maturity generation model, resulting in a demand-driven adaptive supply chain. The implementation of the Demand Driven Operating Model eliminated forecast dependency and led to improved service levels, reduced long lead times, and substantial inventory reductions.

Challenges and Considerations

While DDMRP analytics offer significant benefits for supply chain improvement, there are challenges and considerations organisations should be aware of:

Data Security and Privacy

As organisations collect and analyse sensitive supply chain data, it’s crucial to prioritise data security and privacy. Compliance with data protection regulations and safeguarding against data breaches is essential.

Data Integration

Data integration is a critical component of any successful DDMRP analytics framework. It involves the seamless amalgamation of data from diverse sources within an organisation’s supply chain. However, the process can be quite complex, and organisations often encounter compatibility issues that need to be addressed. Effective data integration strategies are essential to ensure a continuous and unobstructed flow of data within the supply chain.

Skill Set

Data analytics and interpretation are highly specialised skills that play a pivotal role in the effectiveness of a DDMRP analytics framework. Organisations need to invest in training or consider hiring personnel with the necessary expertise to extract meaningful insights from their data.

Professionals who specialise in data analytics should possess a deep understanding of statistical techniques, data mining, machine learning, and predictive modelling. They must also be proficient in data visualisation tools and possess the ability to communicate complex findings to non-technical stakeholders. Data interpretation goes beyond just analysing numbers; it involves understanding the business context and drawing actionable conclusions.

Change Management

Implementing DDMRP and data analytics-driven improvements often brings about significant changes in an organisation’s supply chain processes. Change management strategies are essential to ensure that employees adapt to these changes effectively.

Change management involves preparing employees for changes, garnering their support, and mitigating resistance. When it comes to implementing data analytics and DDMRP, this entails explaining the benefits of data-driven decision-making, clarifying how the changes will affect day-to-day operations, and providing training and support for employees to develop the necessary skills.

Conclusion

In the modern business landscape, organisations must continually adapt and improve their supply chain operations to remain competitive. Demand Driven Material Requirements Planning (DDMRP) offers a data-centric approach to supply chain management, and by leveraging data analytics, organisations can achieve continuous improvement in various aspects of their supply chains.

From demand forecasting to buffer sizing, supplier performance, lead time reduction, and inventory optimization, DDMRP analytics provide a roadmap for better decision-making and greater efficiency. Real-world case studies highlight the tangible benefits of data-driven supply chain improvements, including cost reductions, improved customer satisfaction, and enhanced competitiveness.

However, organisations must also be mindful of challenges such as data security, integration issues, skill requirements, and change management. By addressing these challenges and implementing a robust DDMRP analytics framework, organisations can harness the power of data for continuous supply chain improvement, staying ahead of the competition and delivering value to their customers.

Explore how data analytics can be used to continuously optimize DDMRP processes and drive better results!