Demand Driven Replenishment: Reducing Lead Times and Costs with DDMRP

October 25, 2024

Advanced Metrics for Measuring DDMRP Success: What You Should Track

November 15, 2024Implementing Demand Driven Material Requirements Planning (DDMRP) in complex supply chains presents a powerful yet intricate challenge for businesses striving to increase responsiveness and minimise operational inefficiencies. DDMRP, an evolved approach to traditional MRP and DRP methodologies, introduces a more dynamic way to manage inventory by adjusting based on real demand rather than relying solely on forecast data. In complex supply chains, where dependencies are vast and variable demand is the norm, a thoughtful DDMRP strategy can revolutionise supply chain performance. However, implementing DDMRP is not without its hurdles.

This article will explore the critical success factors and common challenges that companies face when adopting DDMRP, offering a detailed, step-by-step guide to a smooth transition. Through practical advice on change management, stakeholder alignment, and technology integration, we’ll unpack the journey to successful DDMRP adoption.

Understanding DDMRP: A Brief Overview

Before delving into the complexities of DDMRP implementation, it is essential to grasp the basics of this methodology and how it diverges from traditional planning approaches.

What is DDMRP?

Demand Driven Material Requirements Planning (DDMRP) is a planning and execution methodology designed to manage inventory and supply levels in a way that is more responsive to real demand. Unlike traditional methods, which often rely heavily on forecasts, DDMRP places buffers at strategic points to decouple supply and demand variability. By doing so, companies can improve their responsiveness to actual customer orders while reducing the risk of stockouts and excess inventory.

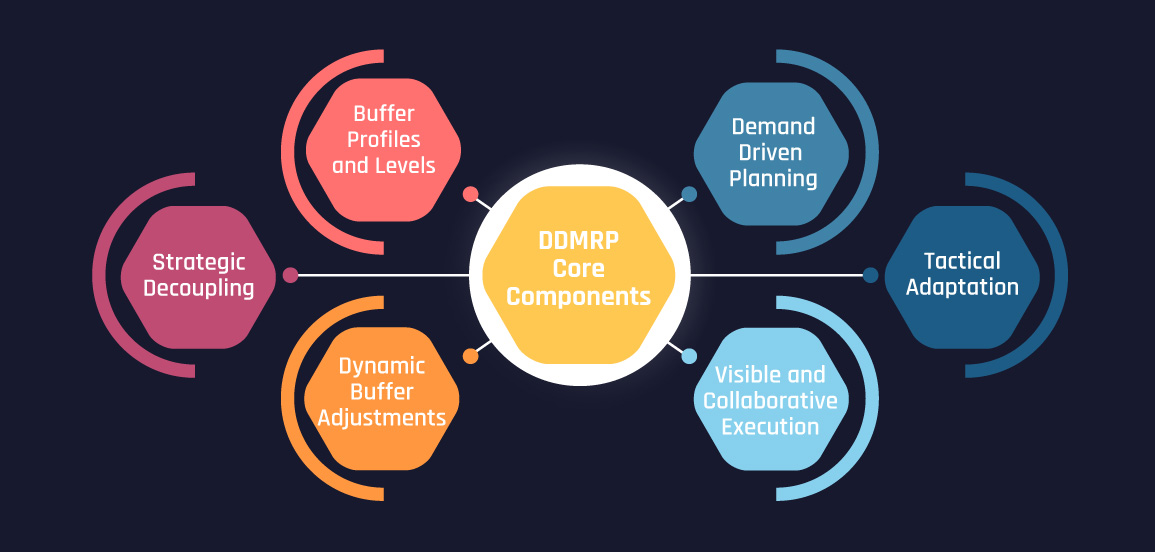

DDMRP has six core components:

- Strategic Decoupling: DDMRP begins with selecting strategic decoupling points, which serve as essential “firewalls” in the supply chain. These points help mitigate demand signal distortions and ensure continuity in supply order generation and execution. Decoupling points are strategically chosen as they directly influence customer lead time and inventory investments. DDMRP applies six key criteria to identify the optimal placement of these decoupling points.

- Buffer Profiles and Levels: To maintain effective decoupling, buffers are carefully sized to manage inventory levels at each decoupling point. In DDMRP, each decoupled item is assigned to a buffer profile, which groups items with similar attributes such as lead time, position in the product structure, and vulnerability to supply or demand fluctuations. By establishing buffer profiles, DDMRP simplifies the management of a large number of decoupled items across the organisation.

- Dynamic Buffer Adjustments: In today’s volatile and dynamic environment, DDMRP enables buffers at decoupling points to adjust in response to changes in demand rate, lead time, or other item attributes. Known as dynamic buffer adjustments, this third component allows buffers to flex based on upcoming events like promotions or seasonal demand. Many of these adjustments are automated within DDMRP-compliant systems, helping organisations respond swiftly to fluctuating conditions.

- Demand Driven Planning: The fourth component, demand-driven planning, is an operational activity that applies specific supply order generation rules—collectively known as the net flow equation—across the configured DDMRP model. This equation is typically run daily across all buffered positions. The resulting demand passes to lower levels, where it activates dependent demand at the next buffered point in a process called decoupled explosion.

- Visible and Collaborative Execution: In DDMRP, a distinct line is drawn between planning and execution. Once an order recommendation has been approved and converted into a scheduled receipt, planning is considered complete. DDMRP execution focuses on managing open orders linked to these scheduled receipts through two types of alerts: Buffer Status Alerts and Synchronisation Alerts. These alerts are designed to identify and resolve disruptions that may affect customer commitments or buffer stability.

- Tactical Adaptation: The final component of DDMRP addresses adjustments to the model through ongoing adaptation based on the Master Settings (the foundational settings from the first three components). This adaptation process is facilitated through Demand-Driven Sales and Operations Planning (DDS&OP), which incorporates both historical performance and anticipated future events. In DDS&OP, the traditional master production schedule (MPS) is replaced, allowing for more agile, demand-driven planning and greater alignment with DDMRP principles.

Step-by-Step Guide to DDMRP Implementation in Complex Supply Chains

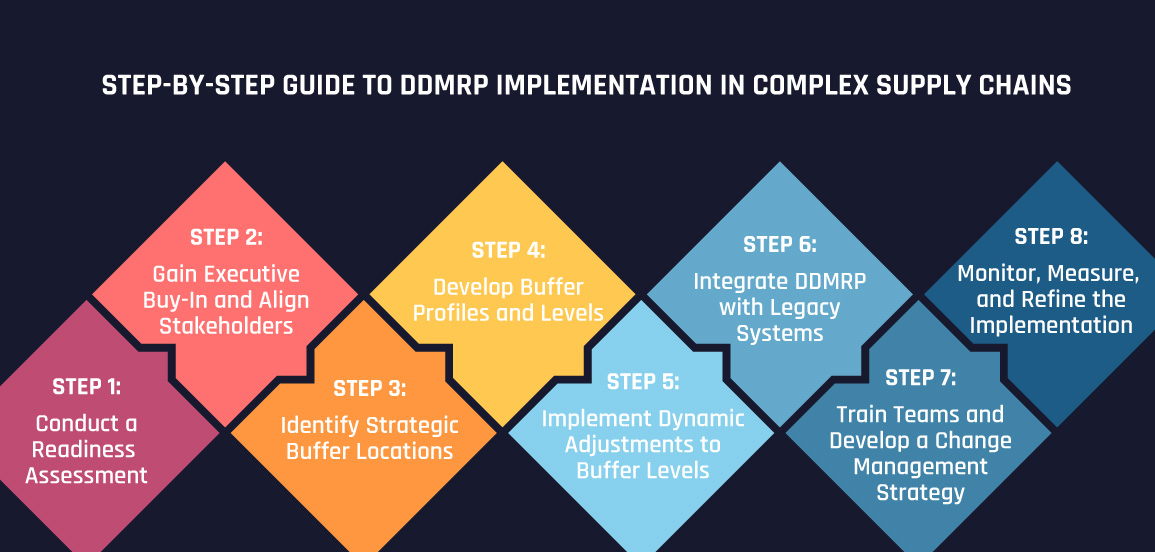

Implementing DDMRP requires a structured approach to ensure a smooth transition and maximise its benefits. Here is a step-by-step guide designed to help companies navigate the process.

Step 1: Conduct a Readiness Assessment

Before beginning a DDMRP implementation, a thorough readiness assessment is essential. This assessment should evaluate factors such as data quality, current technology stack, and existing demand planning processes.

Key Actions:

- Identify critical pain points in the current MRP/DRP setup.

- Assess data quality and availability.

- Examine existing IT infrastructure and compatibility with DDMRP.

Step 2: Gain Executive Buy-In and Align Stakeholders

Successful DDMRP implementation requires alignment across the organisation, especially in complex supply chains where multiple teams must collaborate. Educating stakeholders on DDMRP’s benefits, addressing concerns, and securing executive buy-in can pave the way for a smoother implementation.

Key Actions:

- Present a business case that highlights DDMRP’s value to different stakeholder groups.

- Engage in regular workshops and Q&A sessions to address concerns.

- Form a cross-functional team to oversee the implementation process.

Step 3: Identify Strategic Buffer Locations

A cornerstone of DDMRP is buffer positioning. In complex supply chains, determining the most effective points for buffer placement can be challenging but crucial to achieving optimal results. Factors such as lead times, demand variability, and production constraints should be considered.

Key Actions:

- Use data analysis to identify points in the supply chain that would benefit most from buffers.

- Involve stakeholders across production, warehousing, and logistics to provide insights into practical buffer placements.

- Consider conducting a pilot in a specific product line or region to test buffer efficacy.

Step 4: Develop Buffer Profiles and Levels

Once buffer locations have been determined, it’s essential to establish buffer profiles and set appropriate buffer levels. In complex supply chains, this step is critical for maintaining the right balance between inventory and service levels.

Key Actions:

- Calculate buffer profiles based on historical demand, forecasts or a mix of both, lead time variability, and desired service levels.

- Set up minimum, maximum, and average buffer levels for each profile to guide replenishment.

- Conduct regular reviews and recalibrate buffer profiles as demand patterns shift.

Step 5: Implement Dynamic Adjustments to Buffer Levels

DDMRP emphasises dynamic adjustments to buffer levels as market conditions and demand patterns evolve. This adaptability is particularly valuable in complex supply chains, where demand can be highly volatile.

Key Actions:

- Set up automated alerts to signal when buffer adjustments may be necessary.

- Monitor key performance indicators (KPIs) to assess buffer performance and make data-driven adjustments.

- Conduct regular buffer reviews to refine adjustments based on seasonality or other upcoming demand or supply events and product life cycle changes.

Step 6: Integrate DDMRP with Legacy Systems

A seamless DDMRP implementation requires integration with existing ERP or MRP systems. This step used to be technically challenging in complex supply chains due to data silos, varied system architectures, and the need for real-time data sharing. However, in recent years great advances have been made in standardisation of interfaces, reducing by far the complexity and difficulty of this step.

Key Actions:

- Collaborate with IT teams to map out integration requirements and data flows.

- Test integrations rigorously to ensure data consistency across systems.

- Implement middleware solutions if necessary to facilitate data synchronisation.

Step 7: Train Teams and Develop a Change Management Strategy

Introducing DDMRP involves significant shifts in daily workflows, making change management and training essential components of the implementation process. Employees must understand the principles behind DDMRP to utilise it effectively and to avoid falling back on old practices.

Key Actions:

- Conduct comprehensive training programs covering DDMRP concepts, tools, and workflows.

- Appoint DDMRP champions within each department to support team members and address issues.

- Develop a structured change management plan to ease the transition and encourage adoption.

Step 8: Monitor, Measure, and Refine the Implementation

The final step in DDMRP implementation is to establish a continuous improvement cycle. This means regularly monitoring performance, gathering feedback, and refining processes as necessary. In complex supply chains, this approach is vital to sustaining DDMRP benefits over time.

Key Actions:

- Set up KPIs such as lead time reductions, inventory turnover, and service level improvements.

- Conduct regular post-implementation reviews to identify areas for improvement.

- Engage stakeholders in feedback sessions to understand challenges and adjust as needed.

Critical Success Factors for DDMRP Implementation

Implementing Demand-Driven Material Requirements Planning (DDMRP) in complex supply chains involves more than just following procedural steps; it requires addressing fundamental factors that support a successful transformation. These critical success factors include strong leadership, effective change management, robust data analytics, cross-departmental alignment, and a commitment to flexibility and adaptability.

Strong Leadership and Change Management

Leadership buy-in and active support are essential for overcoming resistance to DDMRP, especially as it may disrupt established workflows. A well-defined change management strategy not only smooths the transition but also reassures employees throughout the process. Leaders who communicate the benefits of DDMRP and foster a supportive environment create a solid foundation for successful adoption.

Real-Time Data and Advanced Analytics

Data is the backbone of DDMRP. Accurate, real-time data allows for informed decision-making, enabling timely adjustments to buffer levels in response to changes in demand. Investment in data analytics capabilities is vital, as it enhances the ability to track trends and respond quickly to fluctuations. High-quality data directly influences DDMRP performance and accuracy, making this factor indispensable.

Alignment Across Departments and Regions

In complex supply chains, achieving interdepartmental alignment is crucial. Functions from procurement to sales and logistics must be well-versed in Demand Driven principles and collaborate seamlessly. Alignment across these areas ensures that the organisation moves in sync, creating a unified response to demand signals and minimising silos.

Flexibility and Willingness to Adapt

Dynamic market conditions require a flexible approach. Buffer profiles, levels, and even buffer locations may need periodic adjustments to keep up with changing demand. DDMRP’s strength lies in its adaptability, making flexibility a key success factor to meet the demands of a fluctuating supply chain environment.

Common Challenges and How to Overcome Them

Implementing Demand-Driven Material Requirements Planning (DDMRP) in complex supply chains offers significant benefits, but companies often encounter specific challenges during the process. Key issues such as data quality, resistance to change, and complex system integrations must be addressed to ensure a smooth implementation.

Data Quality Issues

High-quality data is essential for DDMRP, as accurate information drives decision-making and supports buffer adjustments that reflect real demand. However, poor data quality can significantly hinder DDMRP efforts, leading to ineffective buffer levels and inaccurate demand signals. To mitigate this challenge, companies should establish regular audits and data validation practices. Routine data cleansing can help maintain accuracy, while a robust data governance framework can prevent quality issues from recurring, safeguarding the integrity of DDMRP processes.

Resistance to Change

Switching from traditional MRP methods to DDMRP can be met with resistance from employees who are comfortable with established processes. Such resistance is often fueled by uncertainty and a lack of understanding of DDMRP’s benefits. Transparent communication is essential, along with leadership support to explain the rationale behind the shift. Hands-on training and practical demonstrations of DDMRP’s advantages can help employees feel more confident in the new approach. Empowering a few team members as “DDMRP champions” can also facilitate knowledge sharing and address concerns, fostering a more positive transition.

Complex System Integrations

Integrating DDMRP with multiple ERP and legacy systems can be challenging, especially in complex supply chains with disparate data systems. This process is often time-consuming and technically demanding, as it requires seamless data synchronisation to function effectively. Engaging experienced IT professionals and considering middleware solutions can simplify integration, enhancing compatibility and data flow across systems. Rigorous testing and phased rollouts also help in identifying issues early, ensuring that integration does not disrupt existing operations.

Conclusion: The Future of DDMRP in Complex Supply Chains

As companies continue to navigate an increasingly volatile market landscape, DDMRP offers a pathway to more agile and responsive supply chains. While implementation is challenging, especially for complex supply chains, a structured approach can enable companies to harness the full potential of DDMRP. By focusing on change management, stakeholder alignment, and robust technology integration, businesses can master the art of DDMRP implementation and set themselves up for long-term success.

Get a customised roadmap to mastering DDMRP implementation in your complex supply chain.