Demand Driven Adaptive Enterprise (DDAE): Overview, Benefits, and Case Studies from the Demand Driven Institute (DDI)

How DDAE can Support Manufacturing Companies to Adapt with Global Supply and Demand Shift

September 16, 2022

Benefits of DDAE Model on B2B Supply Chain Management

October 14, 2022In our previous article, we introduced you to the Demand Driven Adaptive Enterprise (DDAE) concept and how it’s changing how businesses operate worldwide.

This article will give you a more in-depth overview of what DDAE is, how it works, and the benefits it brings to companies and organizations.

We’ll also share a few case studies of businesses that have adopted DDAE and seen tremendous success. If you’re thinking of switching to DDAE, these case studies will give you some idea of what to expect.

What Is Demand Driven Adaptive Enterprise (DDAE)?

The Demand Driven Adaptive Enterprise (DDAE) model is a management framework that enables businesses to detect market changes, acclimate to complex and volatile environments, and develop market-driven innovation strategies. Fundamental flow management principles are combined with the emerging complex adaptive systems (CAS) field.

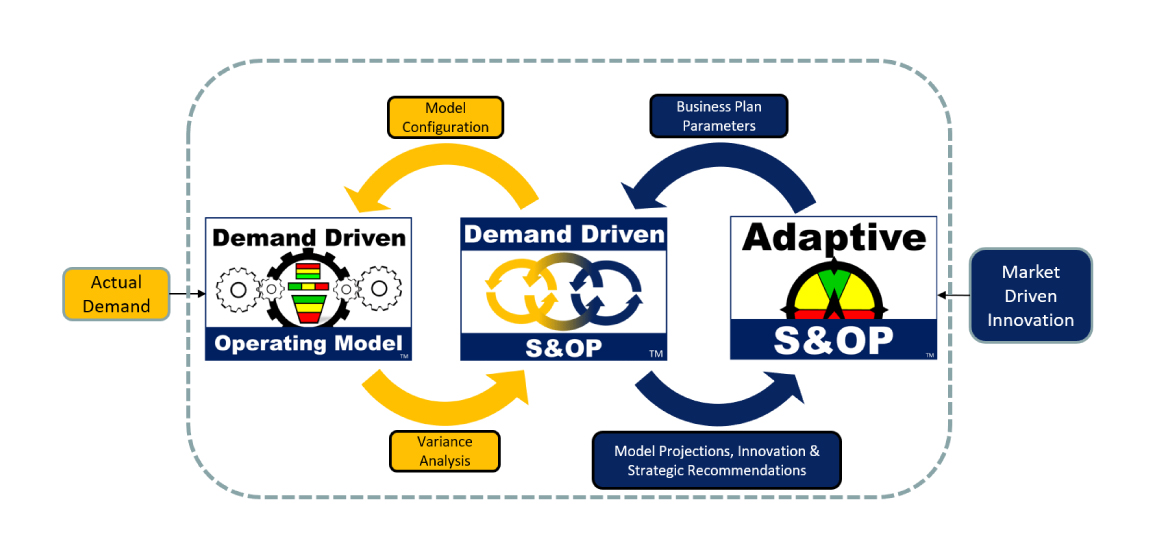

The DDAE model spans the organization’s operational, tactical, and strategic ranges through its three primary components: the Demand Driven Operating Model, Demand Driven Sales & Operations Planning, and Adaptive Sales & Operations Planning.

The model employs an emergence, feedback, and selection process via adaptive cycles to continuously respond and adapt to today’s challenging, changing, and volatile supply chain circumstances.

Overview of the DDAE Model

The Demand Driven Adaptive Enterprise (DDAE) model responds to the global shift in supply and demand. It’s designed to help companies and organizations become more agile and adapt more quickly to changes in the market.

The DDAE model emerged in response to the VUCA environment so that it could provide a comprehensive management model. The demand-driven operating model (DDOM), demand-driven sales and operations planning (S & OP), and adaptive sales and operations planning are the three components that cover the operational, tactical, and strategic levels of management. Through configuration-feedback-reconciliation cycles, the DDAE approach aims to address all three managerial levels consistently. The model relies heavily on relevant ranges for management and relevant information. Management relies heavily on the timely availability of information, and distortions in this information may impede effective system management.

According to Ptak and Smith, the four prerequisites for relevant information understand relevant ranges, tactical reconciliation between suitable ranges, a flow-based operating model, and a flow-based metrics suite. These prerequisites are summarized below:

- Understanding relevant ranges imply that suppositions are valid within appropriate time frames. As a result, assumptions and relevant information for various fields may differ significantly. This applies to operational, strategic, and tactical ranges.

- The relevant ranges must be reconciled continuously and iteratively. As a result, when developing a strategy, a company must consider its operational capability and performance. Similarly, strategy has an impact on operational capability. Finally, the tactical range must be bidirectional to reconcile the operational and strategic ranges.

- The goal of a flow-based operating model is to protect and promote flow. Flow, from this perspective, can be a unifying factor between operations and functions.

- A company must implement appropriate metrics for each relevant range to support a flow-based operating model. These metrics must be compatible across ranges. As a result, such metrics should help the company maintain organizational consistency while controlling variability.

How does DDAE work?

The DDOM effectively connects actual demand and S & OP of the DDAE model’s tactical range. In other words, it corresponds to both operational capability and strategic requirements. As a result, it generates real-time signals based on actual demand.

The DDOM heavily relies on DDMRP, which is “a method for modeling, planning, and managing supply chains to safeguard and promote the flow of relevant information and materials.” DDMRP is a demand-driven operating model’s supply order generation and management engine.

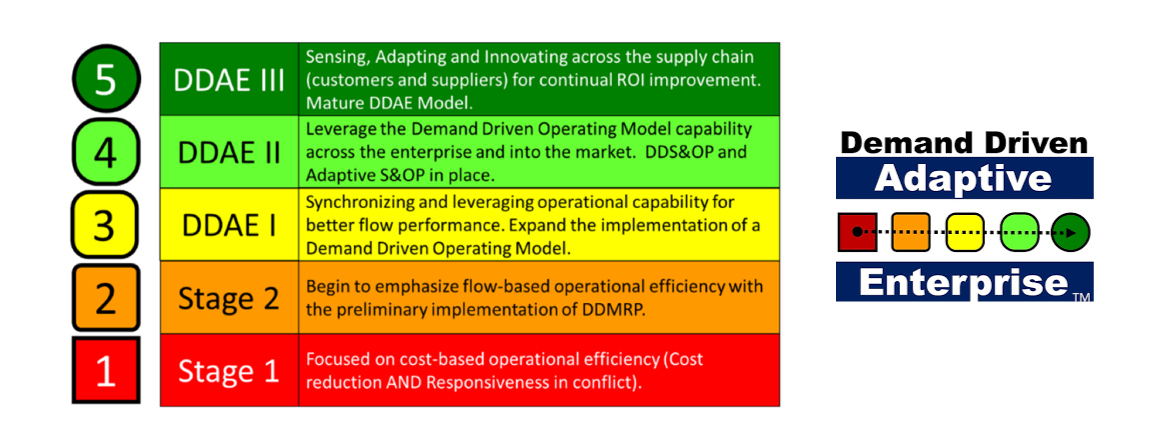

The five stages of DDAE are:

- Stage 1- For most businesses, stage 1 is the starting point. In this context, the managerial approach to maximizing overall results primarily focuses on cost minimization and resource utilization. The flow concept is often overlooked or even ignored.

- Stage 2- The second stage is the first step toward becoming a demand-driven company. The goal is to improve overall performance. Flow is the primary operational driver to enhance OTD. Stage 2 concepts, criteria, and metrics are incompatible with those of Stage 1. As a result, moving to the second stage necessitates a change in methodology, which requires a change in their way of thinking.

- Stage 3 (DDAE I)- The third stage is the first step toward becoming a demand-driven organization. It necessitates the full implementation of DDOM, and its focus is on improving flow performance through tactical analysis, beginning with S & OP.

- Stage 4 (DDAE II)- Stage 4’s goal is to “extend the DDOM capability across the enterprise and into the market.” As a result, the entire organization must comprehend it from a broad perspective.

- Stage 5 (DDAE III)- It is concerned with adapting and improving the organization’s organizational capabilities to facilitate the flow of participants in the supply chain.

The Benefits of DDAE

The Demand Driven Adaptive Enterprise (DDAE) model is gaining popularity for a good reason. This model offers several benefits for companies and organizations. Let’s take a look at some of them.

- DDAE enables companies to react quickly to changing market conditions. As we all know, the market is constantly evolving, and businesses need to be able to adapt quickly to stay ahead.

- It allows companies to respond more effectively to customer demand. In order to be successful, businesses need to deliver what their customers want when they want it.

- It helps organizations optimize their resources. By aligning supply with demand, businesses can make the most efficient use of their resources.

- It fosters collaboration among different departments within an organization. By working together, departments can better understand the customer’s needs and respond accordingly.

So as you can see, there are many benefits to be had by adopting the DDAE model. Are you ready to make the switch?

Case Studies of DDAE Adoption

Case study 1

Company 1 designs and manufactures large customized layouts in small batches (often unitary). Its purchase of raw materials strongly influences delivery times, which may vary extensively depending on the materials’ features. Delivery time for one product generally ranges from 1 to 6 months; one order could take more than a year.

The organization was unaware of the consequences of its decisions on delivery times, productivity, and costs. The impact on workflow was negative, with only the first order progressing continuously until completion. In short, while the productivity status of each section was high, overall OTD execution was poor. The company in Case 1 developed a demand-driven operating model (DDOM) that allowed it to move from a cost-based approach to one that was flow-based in design, purchasing, and job shop activities. Planning, programming, and reporting became easier, enabling permanent updating of data and information.

The DDOM enabled the company to move from a cost-based approach to one that was flow-based in design, purchasing, and job-shop activities. Planning, programming, and reporting became easier, enabling permanent updating of data and information. The time buffers protected uncertainty, making the system more predictable and stable.

After the DDOM was established, the organization’s performance level was monitored over time, focusing on the main metrics. The global performance and stability levels reported were significantly higher than in past results.

Case study 2

- Standard raw materials could be obtained in one or two weeks in the case of Company 2, and orders were completed in three or four weeks.

- Placing orders as soon as possible heightened work in progress (WIP), making each manufacturing section challenging to manage.

- The operational level discovered that delivery date was not a valid criterion for priority management.

- Furthermore, the WIP complicated work management, particularly in terms of priorities.

As a result, the DDOM was similar to the previous model in that the drum schedule was managed through DBR. It served as the foundation for establishing priorities for the rest of the organization, which were updated daily with the latest information.

Because of the dynamic monitoring, the system’s key points over time were prioritized to determine the coherence of the functional and tactical fields based on objective data. The company got closer to DDAE.

As a result, despite the unusual market conditions caused by the pandemic, the tactical analysis of the new model was launched as soon as the system was ready.

The primary metric used to assess system performance was the level of service, which was supplemented by program compliance at the control points. These metrics made it possible to identify critical points and non-compliance causes.

The following are the main findings of this stage:

- The primary issues identified were supply delays and short customer delivery times, which were frequently impossible to meet. Both issues stemmed from the unusual market situation, which was expected to be temporary.

- Internal processes did not cause additional delays to those caused by supplies.

- On the contrary, internal operations frequently recovered supply delays entirely or partially.

- The welding process (immediately following the drum) proved more efficient than the preparation process (immediately before the drum).

- When materials were delivered on time, drum program compliance was nearly 100%.

The results appear to confirm that the system met the defined process requirements.

Similarly, the information system demonstrated its ability to generate timely information required to manage the method according to the model.

Conclusion

The Demand Driven Adaptive Enterprise (DDAE) Model is a departure from the traditional, supply-driven models that have been the norm for centuries. It is based on responding to customer demand as efficiently and effectively as possible.

DDAE has been proven to bring several benefits to companies and organizations, including increased efficiency, better customer service, and higher profits. Several case studies also demonstrate the success of DDAE in practice.

Interested in knowing how Patrick Rigoni can step up the game of your supply chain? Contact us today and get a free consultation.

Patrick Rigoni also offers in-depth DDMRP courses; if you are interested to know more about DDMRP for the supply chain for your company, here is the link to the NEW DDMRP Page.