Market globalization and industrial competition have compelled businesses to maximize profits while considering uncertainties and variations. This is not limited to only B2C and B2B supply chains. Experts and scholars in the B2C and B2B supply chain have developed methods and techniques to handle the stakes of profitability in Supply Chain Management (SCM) practices such as JIT, TOC, KANBAN, and MRP2. The goal is to respond to customer demand systematically while reducing costs by optimizing resource utilization. However, most of these methods failed to adequately manage the increasing uncertainties and variabilities that businesses now face. A recent innovation stands out in a context where supply chain disruptions are becoming the norm: the Demand Driven Adaptive Enterprise (DDAE).

What is DDAE?

The Demand Driven Adaptive Enterprise (DDAE) model is a management framework that enables businesses to detect market changes, adapt to complex and dynamic settings, and build market-driven innovation initiatives. Fundamental flow management ideas are integrated with the growing science of complex adaptive systems (CAS). The DDAE model covers the organization’s operational, tactical, and strategic ranges through its three key components: the Demand Driven Operating Model, Demand Driven Sales & Operations Planning, and Adaptive Sales & Operations Planning. The model employs an emergence, feedback, and selection process via adaptive cycles to continually adjust and adapt to today’s complex, dynamic, and unpredictable supply chain situations.

Since 2011, DDAE has attempted to synthesize solid practices from past material management approaches while also introducing some significant advances. Compared to Kanban and MRP2, it has demonstrated its potential to be adaptable and robust in a disrupted situation. DDAE, despite growing attention from practitioners and academics, is still in its infancy and requires more contributions to solidify both the approach and the accompanying decision support systems.

DDAE and Demand Driven Institute(DDI)

During the previous decade, the Demand Driven Institute (DDI) concentrated on the operating model (Demand Driven Operating Model or Demand-Driven Material Requirement Planning) while remaining hazy on the tactical and strategic levels of DDAE. Particularly, the strategic layer of DDAE, Adaptive Sales and Operations Planning (AS&OP), has received little attention and would benefit significantly from more research to enable real deployments. One significant problem among all potential improvements is the granularity level that should be employed to complete the AS&OP decision-making. Some say simple aggregating computations should handle it at the product level. In contrast, others say it should be modeled directly as aggregated (through product families) to enable the analysis and associated choices. The latter has long been proven to provide significant benefits, such as avoiding personnel changes, lowering overheads, and enhancing production efficiency. However, it has also been proved that implementing such a Variant in a real-world environment is not straightforward.

Using DDAE Metrics to Ensure Success in the B2B Supply chain

Metrics are critical to understanding and maintaining the outcomes of any corporate change, and DDAE is no exception. The DDAE model incorporates operational, tactical, and strategic indicators.

Operational

GOAL – Determine what individuals should begin, continue, or discontinue to increase material flow.

What questions do you need to ask to achieve the operational goal?

Reliability – entails how effectively we can stick to the model, strategy, schedule, and market expectations.

Stability: How much fluctuation do our results have?

Speed: Are we completing the correct task as rapidly as possible?

Tactical

GOAL – Determine how successfully individuals are capturing waste-reduction possibilities.

What questions do you need to ask to achieve the tactical goal?

Waste reduction potential – How successfully have we identified flow barriers?

Expenses: Are we spending the bare minimum necessary to attain our objectives?

ROI – Have we maximized the system’s return based on tactical opportunities such as

Strategic

GOAL – Determine how our inventions contribute to the company’s bottom line.

What questions do you need to ask to achieve the strategic goal?

Contribution margin: Have our ideas resulted in increased growth?

Working capital: Is enough working capital generated to safeguard and encourage flow?

Customer base: Have we established and built a robust company foundation?

Stages of DDAE

The DDAE model has a defined development path for companies to follow as they mature their demand-driven transformation. This path is divided into five distinct stages.

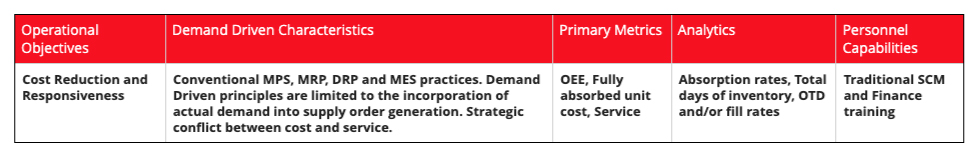

First stage: operational efficiency (cost)

The development path begins where most businesses are today: constantly struggling to drive operational efficiency by controlling or minimizing costs. It’s not that flow is ignored in these systems, but any flow-based metrics, such as on-time delivery, are constantly competing with cost-based metrics and objectives. This is a recipe for disaster in today’s hyper-competitive and volatile markets. These companies’ characteristics are listed below.

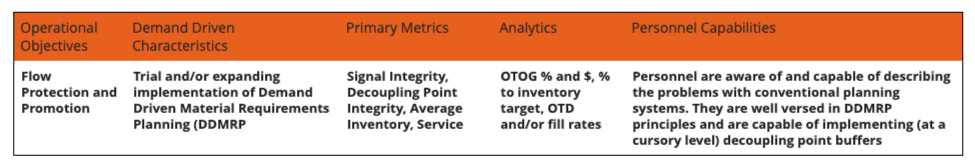

Second stage: operational efficiency (FLOW)

The second stage of a company’s transformation into a Demand Driven Adaptive Enterprise begins. Moving from Stage 1 to Stage 2 necessitates a significant conceptual shift in one’s thinking and knowledge of what is genuinely “efficient” from a system standpoint. This transition is not minor since it necessitates a fundamental shift away from the traditional concentration on cost. The graph below depicts the discrepancy in perspectives. Stage 1 links ROI improvement to improved cost performance, whereas Stage 2 links ROI improvement to improved flow performance. These two points of view are not compatible; in fact, they are opposed.

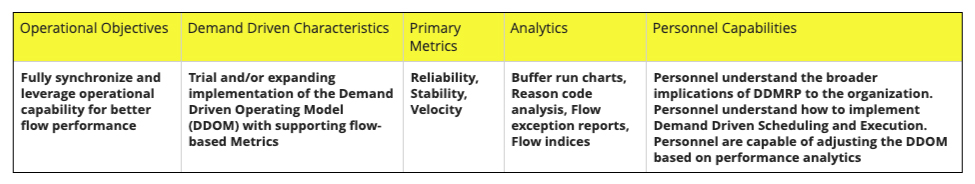

Third Stage: DDAE LEVEL 1

Stage 3 is the first level at which a business can genuinely claim to be “Demand Driven.” As a result, the stage is known as “DDAE Level I.” It has a fully functional Demand Driven Operating Model (DDMRP, Demand Driven Capacity Scheduling and Demand Driven Execution methods). In more prominent firms with several locations and vertical integration, the transition from DDAE Stage 2 to DDAE Stage 3 might take years. This reflects a significant (but enormously beneficial) change in operational strategies affecting supply order development, resource scheduling, operational execution, and metrics. Demand Driven Performance – Using Smart Metrics goes into great detail about this stage. A maturing Stage 3 corporation will eventually be hampered by a lack of alignment with other organizational activities.

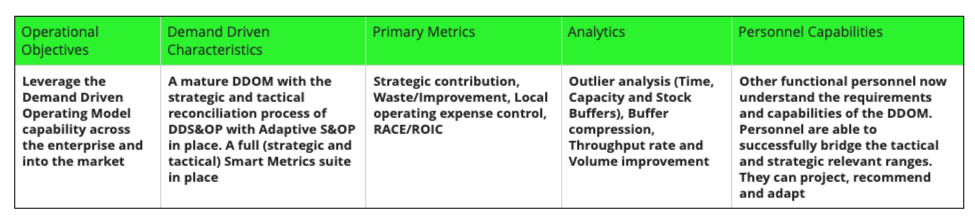

Fourth Stage: DDAE LEVEL 2

The Fourth Stage (DDAE Level II) describes the spread of Demand Driven ideas throughout the enterprise. Tactical reconciliation has been implemented, and the firm understands how to exploit the mature DDOM capabilities in the market and across the enterprise for improved financial performance. Its employees comprehend and see the company as a system. Finance, Engineering, Information Technology, Marketing, Sales, and Strategic Planning are all aware of leveraging the DDOM as a competitive weapon and can communicate using a common flow-based vocabulary.

Benefits of DDAE

In a dynamic environment, the significance of agility is self-evident, but it isn’t always obvious. By providing a defined process for moving effectively between market demand and market-driven innovations, The DDAE model helps B2B organizations to:

- Create tactical and strategic feedback loops to discover and implement changes.

- Understand the influence of plans on corporate operations.

- Daily, use natural, visual cues to take action.

- Align around a common understanding of the business.

Other benefits of using the DDAE model on B2B supply chain management.

The DDAE model can help to improve communication and coordination between different members in the B2B supply chain.

- The DDAE model can help to optimize the resources and inventory in the B2B supply chain.

- The DDAE model can help to improve the quality of products and services.

- The DDAE model can help to shorten the lead time and delivery time.

- The DDAE model can help to improve customer satisfaction.

- The DDAE model can help to reduce the overall cost in the B2B supply chain.

Conclusion

The Demand Driven Adaptive Enterprise (DDAE) Model covers an organization’s operational, tactical, and strategic ranges, allowing it to continually and successfully adjust to today’s complex and dynamic supply chains. It blends core flow management ideas with the burgeoning new science of complex adaptive systems (CAS). It is how successful firms will operate in the twenty-first century.

In a situation where the DDAE model is becoming increasingly significant for managing material flow in Supply Chains when it comes to implementing it to your B2B Supply chain, you should always conduct a study and confer with certain specialists who are well-versed in DDAE.

Interested in knowing how Patrick Rigoni can step up the game of your supply chain? Contact us today and get a free consultation.

Patrick Rigoni also offers in-depth DDMRP courses; if you are interested to know more about DDMRP for the supply chain for your company, here is the link to the NEW DDMRP Page.