Forecast on the Impending Massive Global Shift in Supply and Demand

September 9, 2022

Demand Driven Adaptive Enterprise (DDAE): Overview, Benefits, and Case Studies from the Demand Driven Institute (DDI)

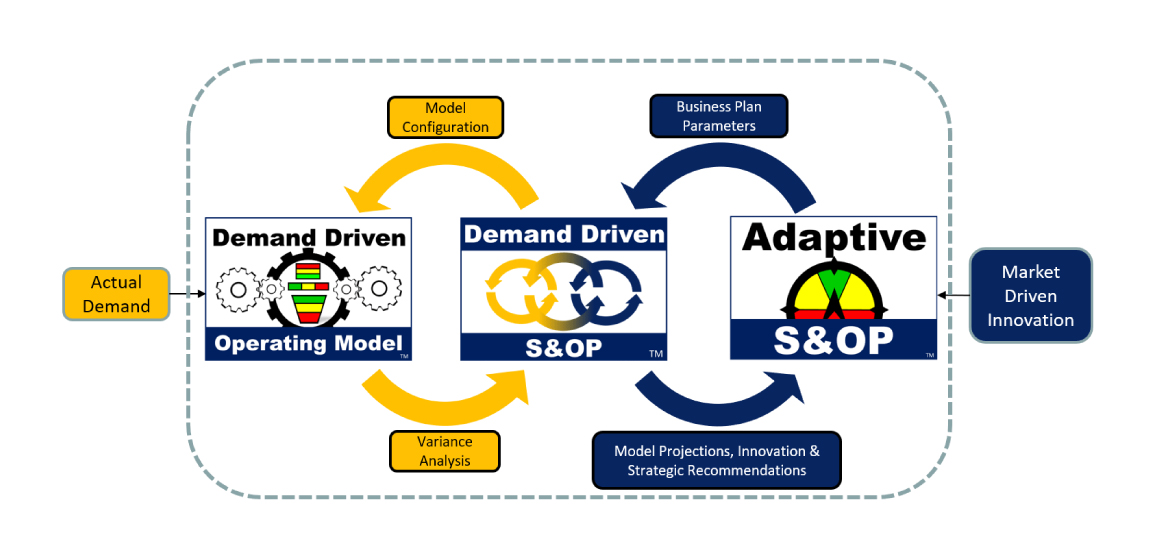

September 23, 2022The Demand Driven Adaptive Enterprise Model, or DDAE Model, is a management and operational model that enables companies to adapt to complex and volatile environments. It utilizes a constant system of innovation and feedback between three primary components; a Demand Driven Operating Model, Demand Driven S&OP, and Adaptive S&OP.

This model can be applied in any industry. Still, it is especially beneficial for manufacturing companies looking to align their supply and demand to stay ahead of the curve with global market shifts.

In this post, we’ll explore the benefits that manufacturing companies can receive when they apply the DDAE Model in their supply chain. We will also see what Carol Ptak and Chad Smith talked about the framework for transforming a company into a Demand Driven Adaptive Enterprise.

What Is the DDAE Model?

The Demand Driven Adaptive Enterprise (DDAE) model is a management framework that enables businesses to detect market changes, adapt to complex and volatile environments, and develop market-driven innovation strategies.

Fundamental flow management principles are combined with the emerging science of complex adaptive systems (CAS). The DDAE model spans the organization’s operational, tactical, and strategic ranges through its three primary components: the Demand Driven Operating Model, Demand Driven Sales & Operations Planning, and Adaptive Sales & Operations Planning.

The model employs an emergence, feedback, and selection process via adaptive cycles to continuously respond and adapt to today’s complex, changing, and volatile supply chain circumstances.

The DDAE model enables companies to adapt rapidly to changing global supply and demand patterns.

How Can the DDAE Model Help Manufacturing Companies?

The Demand Driven Adaptive Enterprise model is a management and operational model designed to enable enterprises to adapt to complex and volatile environments. The model utilizes a constant system of innovation and feedback between three primary components; a Demand Driven Operating Model, Demand Driven S&OP, and Adaptive S&OP.

This three-fold system ensures that businesses are constantly adjusting to changing global demands for their products.

The Demand Driven Operating Model provides that the demand for products is always driving production. Demand Driven S&OP ensures that the product flow between supplier and customer is always in balance. And Adaptive S&OP allows businesses to adapt rapidly to shifts in customer demand or supplier capacity.

The Three Primary Components of the DDAE Model

We discuss more in-depth, each of the 3 primary components of the DDAE model below:

The Demand Driven Operating Model

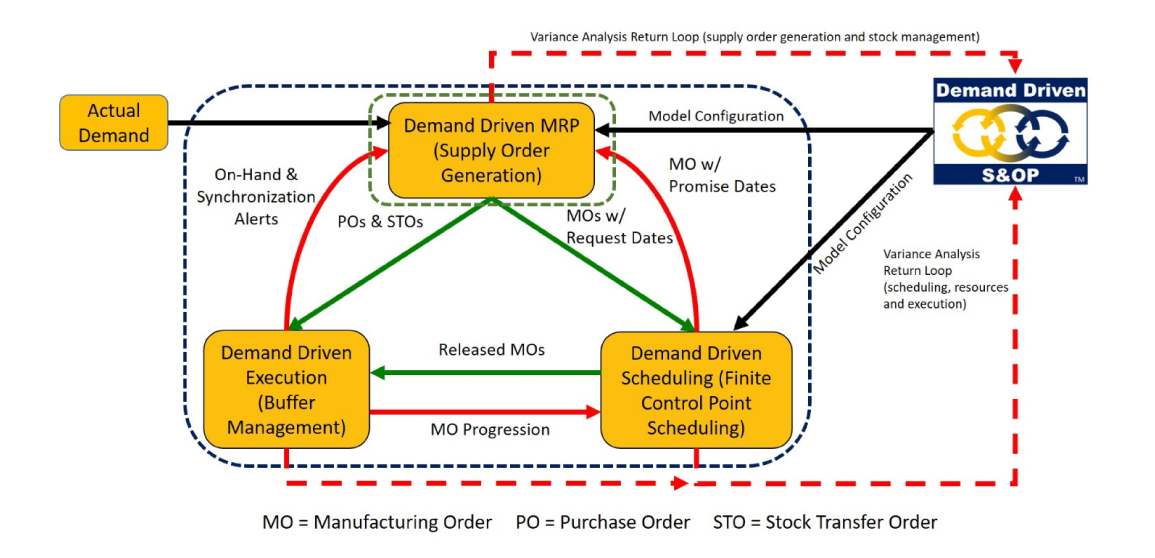

A Demand Driven Operating Model (DDOM) is a model for supply order generation, operational scheduling, and execution that uses actual demand in conjunction with strategic decoupling and control points, as well as stock, time, and capacity buffers, to create a predictable and adaptable system that promotes and protects the flow of relevant materials and information within the operational selected period (hourly, daily and weekly).

The Demand Driven Sales & Operations Planning (DDS&OP) process determines the key parameters of a DDOM to meet stated business and market objectives while minimizing working capital and expedite-related expenses.

The Demand Driven S&OP process

Demand Driven S&OP is a tactical bi-directional integration point between the strategic and operational relevant decision-making ranges in a Demand Driven Adaptive Enterprise.

Demand Driven S & OP maintains and updates the parameters of the DDOM based on the current and arising business method supplied by Adaptive S&OP and a systematic review of past and projected DDOM performance, primarily in the tactical relevant range.

To provide appropriate DDOM projections, DDS&OP evaluates scenarios proposed in the Adaptive S&OP process. Furthermore, it recommends strategic leadership changes and internal innovations involving DDOM’s future capability and performance.

Adaptive Sales and Operations Planning

The integrated business process of adaptive sales and operations planning allows management to define, direct strategically, and manage relevant data in the strategic, relevant range and throughout the enterprise. Market-Driven Innovation is used in conjunction with Operations Strategy, Go-to-Market Strategy, and Financial Strategy to generate strategic data and demands for tactical reconciliation and strategic projection to create and drive adaptation effectively.

How Visibility is Gained to Relevant Information and Optimally Manage Flow

There are four prerequisites for relevant information:

- Understanding relevant ranges

- Implement a flow-based model

- Tactical reconciliation

- Implement flow-based metrics

Understanding relevant ranges

The relevant ranges in the DDAE model have three types: operational, tactical, and strategic.

The operational range uses DDOM to calculate the longest decoupled lead time. It is estimated in hourly, daily, or weekly time buckets.

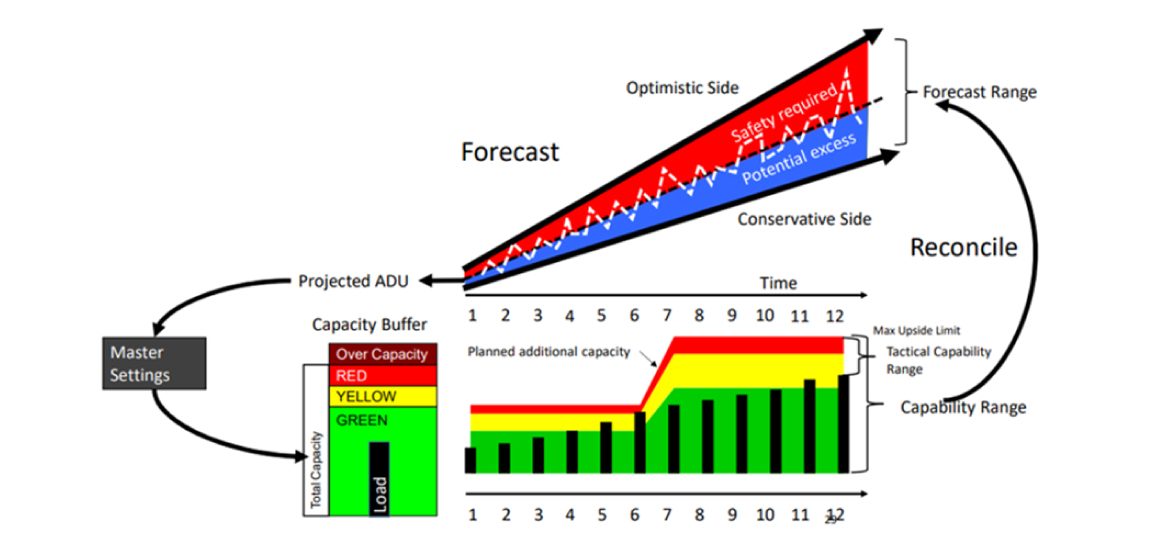

The tactical range uses Demand Driven S & OP. It blends the present, short-range past, and future to find at least the cumulative lead time of the product.

The strategic range is based on market-driven innovation. It uses adaptive S & OP to calculate the product’s yearly, quarterly, or monthly cumulative lead time and beyond.

Implement a flow-based model

This model combines MRP, DRP, Lean, Theory of Constraints, Factory Physics, and Six Sigma.

Some of the functions of this stage are:

- Adjusts operations to meet actual demand.

- For lead time compression and variability (bullwhip) mitigation, decoupling points should be strategically placed.

- Control points for schedule synchronization should be strategically placed.

- Stock, time, and capacity buffers protect decoupling and control points.

Tactical Reconciliation

This stage consists of 6 main parts:

- Tactical Analysis (Demand Driven Variance Analysis)

- Tactical Projection (Model performance projected within the tactical range)

- Tactical Configuration/Reconciliation (adjustment of the model to the changing environment and strategy)

- Tactical Exploitation (short-term supplements to flow as needed)

- Strategic Recommendation (improvement ideas for model performance that require senior-level approval)

- Strategic Projection (projecting model performance within a strategic range).

With S&OP, DDOM can be reconciled. The DDOM allows a single forecasted number to be automatically converted to a range of capabilities. This range of capability can then be compared to the forecast range to determine whether the capability range is sufficient.

If demand is low, stock exposure is limited. If the range is insufficient, the model can be adjusted via Master Settings.

Implement flow-based metrics

A resilient enterprise is created by strategic buffering combined with well-defined CAS characteristics, which is the key success factor for this model. The characteristics are:

- Boundaries – Relevant ranges primarily define these.

- Chaos’ Edge – Specific zones and metrics that are closely monitored.

- Signals – Highly intuitive and visually appealing signals.

- Signal Strength – Highly intuitive and visually appealing signals that provide an instant sense of relative priority.

- Feedback Loops – Clearly defined tactical and strategic feedback processes and mechanisms

- Defined Adaptive Agents – Defined adaptive agents can be found in all relevant ranges.

What Is the Role of Innovation and Feedback in the DDAE Model?

Innovation and feedback are two essential aspects of the DDAE model. Let’s take a closer look at what they mean.

Innovation refers to introducing new or improved products, services, or processes. It’s about creating value for your customers and staying ahead of the competition.

Feedback, on the other hand, is the process of giving and receiving information that helps you learn and improve what you’re doing. It’s essential to ensure your business is constantly evolving and meeting your customers’ needs.

The DDAE model brings these two concepts together, so you can continually create value for your customers and stay ahead of the competition.

Conclusion

Companies should invest in people’s ability to think and solve problems systematically.

If companies cannot think systemically, any organization will be unable to observe, identify, and resolve distortions in relevant information and materials at the systemic level.

This means that your company cannot consider and adapt to flow at all levels. Senior management’s primary responsibility should be to ensure and maintain a framework for the four prerequisites for relevant information.

Interested in knowing how Patrick Rigoni can step up the game of your supply chain? Contact us today and get a free consultation.

Patrick Rigoni also offers in-depth DDMRP courses; if you are interested to know more about DDMRP for the supply chain for your company, here is the link to the NEW DDMRP Page.