Jobs and Careers with DDMRP Education and Certification

March 18, 2022

DDMRP in Aerospace Supply Chain Management

April 1, 2022Demand-Driven Replenishment, rather than typical MRP techniques, help you plan and manage supply chains efficiently depending on consumer demand. This is accomplished by deliberately decoupling material flows, making the supply chain less vulnerable to disruptions protecting the flow with dynamically regulated buffer stock levels for key products.

SAP: S/4HANA update

SAP Business Suite 4 is the latest version of SAP Business Suite. SAP HANA is a business suite based on SAP’s in-memory computing platform and proprietary operational database system, SAP HANA. SAP S/4HANA has been dubbed “SAP’s biggest change to its ERP strategy and platform in over two decades,” implying that S/4HANA is simply a new ERP system overhaul.

DDMRP is available in two editions in the SAP S/4HANA product offering: SAP S/4HANA Cloud and Integrated Business Planning (IBP) and SAP S/4HANA On-Premise. On a high level, there was ECC and APO before S/4HANA and IBP, and now there is S/4HANA and IBP.

How can you implement DDMRP using SAP’s Flori application?

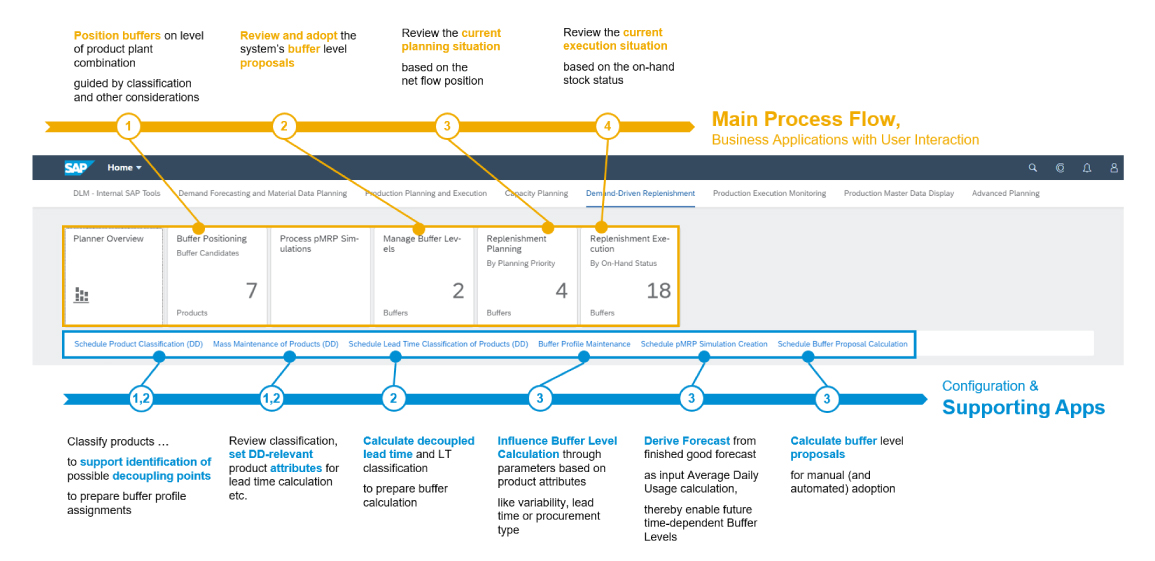

For implementing DDMRP, you should follow the following two steps:

- Configure the Flori application

- Operate the Flori application

First, You have to identify the relevant DDMRP materials, then in the material master, MRP 1 view, update the MRP type D1. Second, there are seven tabs in the application to implement the DDMRP. The seven tabs are as follows:

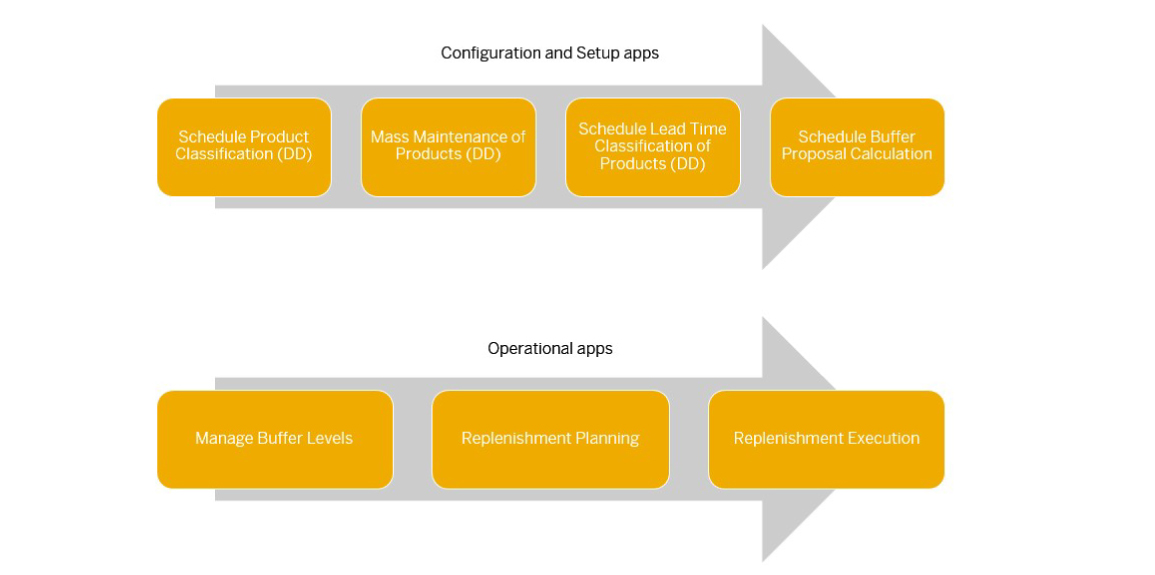

1. Schedule Product Classification (DD)

You can classify your items using this tab by methodically analyzing them within a given assessment interval based on their goods issue value (ABC classification), utilization across BOMs (PQR classification), and variance in actual demand (XYZ classification). Classifying your products will aid in determining whether they are appropriate for Demand-Driven Replenishment and defining inputs for buffer settings.

2. Mass Maintenance of Products (DD)

You can use this tab to view and edit product details (master data records) relevant to Demand-Driven Replenishment. You can check the results of your classifications in this app once you’ve categorized or re-classified your products and then select suitable products for Demand-Driven Replenishment based on the results. You can utilize the mass change capability to change the master data records for multiple products at once.

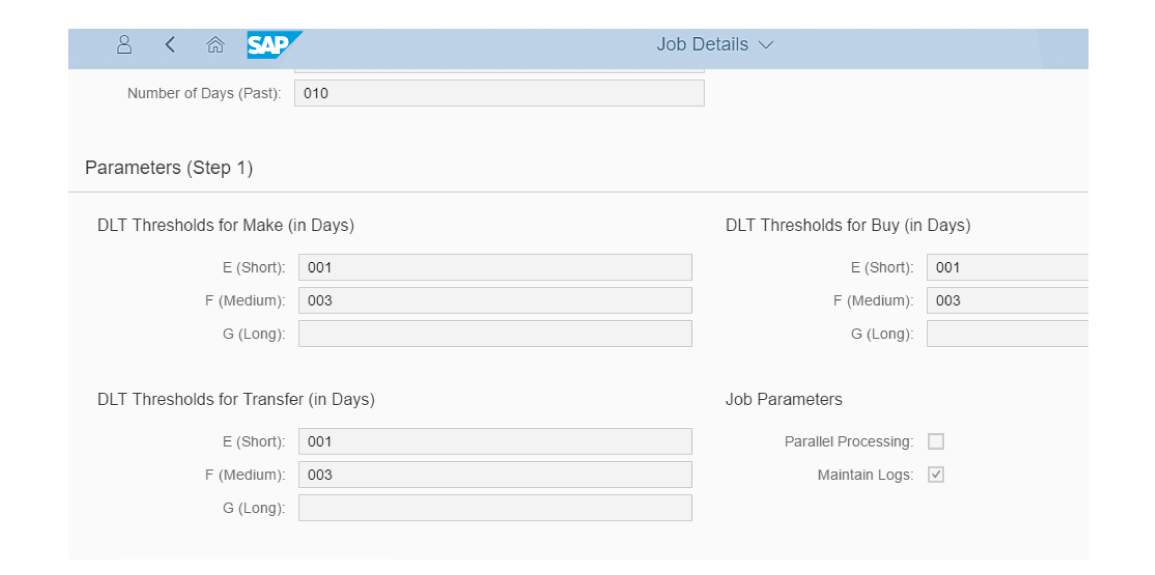

3. Schedule Lead Time Classification of Products (DD)

With this tab, you may classify your Demand-Driven Replenishment-relevant products by analyzing them across a chosen assessment period based on their Decoupled Lead Time (EFG classification). It will be easier to establish inputs for your buffer settings if you classify your products based on their Decoupled Lead Time (DLT). You can also schedule runs to re-classify your products regularly to maintain their classifications current, ensuring accurate results as you move forward with Demand-Driven Replenishment.

4. Schedule Buffer Proposal Calculation

You can use this tab to generate buffer (stock) level proposals for your Demand-Driven Replenishment-relevant products based on average daily usage, decoupling lead time, buffer profiles, and various other parameters. You can also plan runs to recalculate the buffer proposals regularly to keep them current, ensuring that you maintain adequate inventory levels while using Demand-Driven Replenishment.

.

5. Manage Buffer Levels

By regulating the safety stock, reorder point, and maximum stock through buffer proposals for efficient Demand-Driven Replenishment, you can ensure products are available when needed.

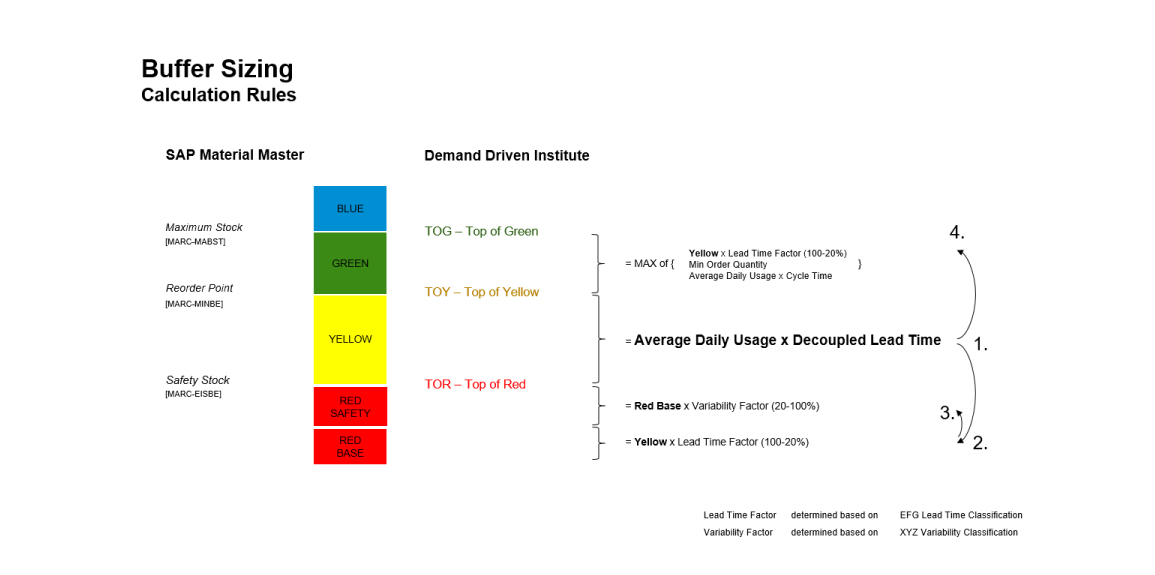

How to calculate different buffers?

For calculating buffers, several factors are taken into consideration. Some of the buffers and their calculation logic are as follows:

- Average Daily Usage- The average usage of a product or component daily, calculated based on the demand over a selected averaging interval.

- Averaging Interval- You can use the Mass Maintenance of Products (DD) tab to set an averaging interval, a rolling interval defined in the form [-x days], referring to the current date. You can use This interval to calculate the Average Daily Usage (ADU) for that date based on the daily usage and to calculate the Decoupled Lead Time (DLT).

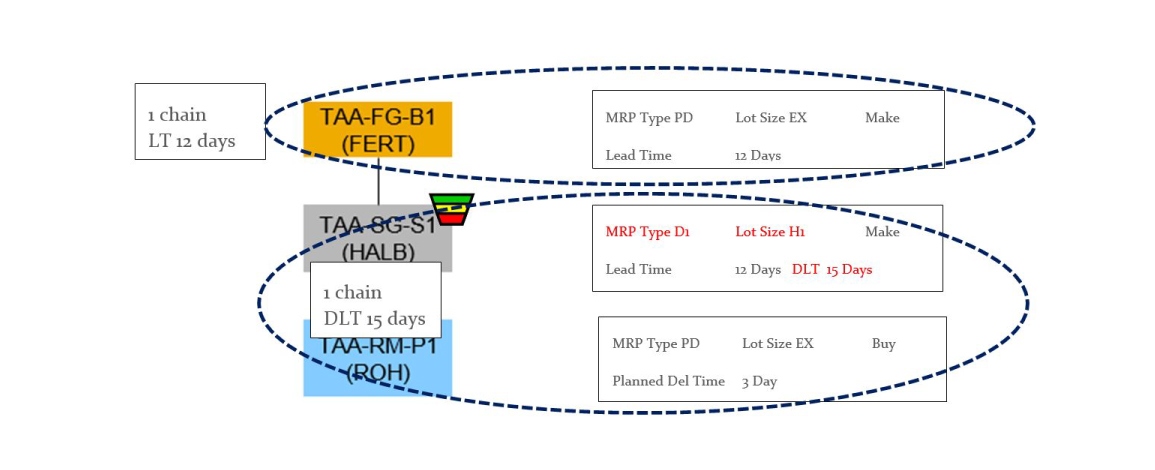

- Decoupled Lead Time- A sum of the longest lead times of non-buffered products in a sequence headed by a buffered (DD-relevant) product in a BOM, adding up to a cumulative lead time for the buffered product.

- Minimum Order Quantity- The lowest product quantity for which an order can be placed to replenish the stock buffer, decided Minimum Order Quantity by logistical, contractual, or cost considerations.

- Buffer Profiles– Buffer Profiles are a set of buffer control parameters. They are assigned to DD-relevant products based on their classification concerning lead time and variability and their procurement type. Every DD-relevant product has a Lead Time Factor and a Variability Factor assigned to it based on its given buffer profile that helps calculate the buffer level proposals for that product.

6. Replenishment Planning

This tab gives you a quick summary of the buffer data organized by planning priority. You can use this data to schedule replenishment to avoid stock shortages and delays in fulfilling production or sales orders due to insufficient stock.

7. Replenishment Execution

This tab allows you to monitor the current stock status for each product and ensure that enough on-hand stock is available for production. The planner can use this information to speed up replenishment by contacting the purchase order’s supplier or the component manufacturing order’s production supervisor.

SAP’s latest book on DDMRP

SAP has also released a book on the DDMRP: Introducing Demand-Driven Replenishment (DDMRP) in SAP S/4HANA, also featured on the Demand Driven Institute’s website. It walks you through each step of a DDR project. You’ll learn how SAP S/4HANA uses DDR to recalculate the standard MRP elements—classifications, stock positioning, lead time, and buffers—for lower variability and also how DDR reduces demand-supply variability. You and discover SAP Fiori apps for inventory management, lead time, and improve the accuracy of your material planning!

Reach out to Demand Driven expert Patrick Rigoni to learn more about what DDMRP can do for you and your team!

Images source: blogs.sap.com